At a time when global agriculture faces the dual challenge of feeding a growing population while reducing its environmental footprint, the CONFETI project stands as a pioneering initiative aimed at reshaping how synthetic fertilisers are produced and applied.

Funded by the European Union’s Horizon Europe programme, CONFETI (short for ‘Green Valorization of CO2 and Nitrogen Compounds for Making Fertilizers’) is developing one of the most environmentally sustainable urea production systems to date. Its approach combines CO2 and nitrogen capture with renewable energy technologies to generate fertilisers in a circular, decentralised and low-impact process.

Now marking the end of its first year, CONFETI has already delivered critical scientific breakthroughs, laid the groundwork for innovative systems and set a strong trajectory toward real-world applications. This article reflects on the achievements and methodologies that have brought CONFETI to this milestone.

The project is driven by a transdisciplinary consortium led by the Universitat Autònoma de Barcelona (UAB), and composed of leading institutions such as the Institut de Microelectrònica de Barcelona (IMB-CNM, CSIC), University of Antwerp (Uantwerpen), CNRS, Université Paul Sabatier Toulouse III, Università di Pisa, BIOO, CIEMAT and Iowa State University. Together, they bring expertise in electrochemistry, photocatalysis, materials science, environmental science, electronics and biotechnology.

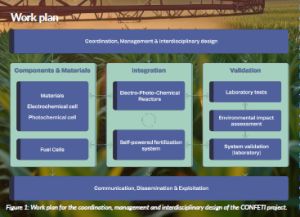

CONFETI’s work plan is organised across interrelated research areas called work packages (WPs), each dedicated to a specific aspect of the project. This structure allows different technologies to evolve in parallel while staying interconnected.

Advances in CO2 capture: solid-state electrolytes

CONFETI’s progress in solid-state electrolytes focuses on the development of hybrid membranes that combine mechanically robust polymers with tailored ionic liquids. These membranes marry gas sorption with ionic transport in a single layer. By systematically varying the location of reactive sites (within the polymer backbone, the ionic liquid, or both), the team has created a library of capture media that combines high gas sorption capacity with electrochemical compatibility. The best candidates reach ionic conductivities close to 0.5 mS cm-1 while holding sorbent phases of up to 80 wt%. At 25 °C and 400 ppm CO2, the best of the materials prepared absorb 4 mg CO2 per g membrane, reaching half-capacity in under 100 minutes. Yet, they remain chemically stable when bathed in electrolytes containing 25 wt% nitrate.

Equally important for real-world operation, month-long storage trials show no measurable decline in conductivity or capture performance, confirming that the membranes can shuttle CO2 to the cathode without clogging or degradation. This resilience is essential because the same layer must tolerate the alkaline, nitrate-rich environment necessary for electrochemical urea synthesis. With these benchmarks achieved, manufacturing has shifted from small coupons to electrode-scale sheets. This allows the most promising formulations to be clamped directly into CONFETI’s flow cell for continuous trials. Successful integration will be a decisive step toward decentralised, low-carbon fertiliser production.

Electrocatalytic conversion: flow cell innovation

Electrochemical work within CONFETI is anchored by a custom-built flow cell. Its membrane window serves as both the CO2 capture interface and the cathodic inlet for reactants. Using silver as a benchmark catalyst, this reactor has surpassed the initial target of 10 mA cm-2 geometric current density set by the consortium. This figure was achieved while the operating parameters for CO2 and nitrate reduction were still being optimised in isolation. Screening of pH, nitrate concentration and gas flow separately confirms that the two half-reactions peak under different conditions. This information is now guiding the search for a unified operating point that maximises urea formation.

Material development is proceeding on several fronts. Laser ablation of commercial electrodes tailors surface hydrophobicity to mitigate electrolyte flooding and extend operational life. Catalyst selection balances activity with abundance; while silver and indium offer the greatest urea selectivity, cost and supply constraints are driving efforts to reduce loading. Nitrogen-doped carbon supports are being evaluated for their ability to enhance CO2 adsorption and kinetics. The immediate objective is to pair the top-performing capture membrane with an optimised Ag- or In-based catalyst to boost Faradaic efficiency without sacrificing current density, thus advancing the system toward industrial relevance.

Electrochemical conversion powered by photocatalytic nitrate recovery

In addition to electrochemical conversion, the CONFETI project employs a sunlight-driven strategy to tackle nitrate pollution and reintegrate it into the fertiliser cycle. While conventional photocatalytic materials are effective, their wide band gap limits absorption to the ultraviolet portion of sunlight. To broaden spectral utilisation without relying on costly noble metals, the team incorporated a commercial metal oxide into a semiconductor matrix, forming a composite that is responsive to visible light and enhances charge separation while reducing electron-hole recombination. In anoxic, bench-scale experiments, this material has consistently converted nitrate into ammonia. Current efforts are focused on achieving the more complex carbon-nitrogen coupling required for urea synthesis.

Initial trials in scale-up photoreactors corroborate ammonia production at the pilot scale and demonstrate that the composite catalyst remains active under real-sun conditions and realistic hydraulic loads. However, determining long-term viability hinges on catalyst durability and mechanistic insights, both of which will be addressed through detailed spectroscopic studies and extended outdoor campaigns scheduled for the coming year.

Bioenergy systems: soil microbial fuel cells

A defining aspiration of CONFETI is to operate its reactors using virtually no external electricity. To this end, the CONFETI team has installed soil-microbial fuel cells (SMFCs) to harness the metabolic activity of soil microorganisms and generate a steady current. In the first project year, two technical challenges emerged in the production of bionanodes: maintaining bacterial viability within the immobilisation matrix and increasing electronic conductivity without toxic dopants. These challenges were overcome by tailoring a silk-fibroin scaffold, chosen for its biocompatibility, and by incorporating carefully dosed conductive additives. For the biobattery itself, one of the biggest challenges has been maximising power output to supply the final prototype while minimising reliance on solar energy. To address this, we developed a new version of biobatteries that can operate buried and interconnected, increasing the power output.

Electrical conditioning is equally crucial. Since raw microbial power is low and variable, the consortium built harvesting electronics that buffer and reshape the current. These electronics deliver a regulated waveform identical to that of a photovoltaic micro-panel. This architecture allows SMFC strings and solar modules to operate as a single hybrid source. When the light is plentiful, the PV dominates. During overcast or nocturnal periods, the biobatteries maintain baseline power, ensuring that the electrochemical and photochemical reactors never fall below their voltage threshold.

Field prototypes demonstrate the agronomic benefits of this underground design. Interlinked SMFCs supply energy, and their ability to operate buried enhances moisture retention inside the biobattery and their long-term stability. Their modular design simplifies deployment in various climates and supports several smart city scenarios currently under evaluation. These scenarios involve urban green spaces hosting discreet energy-fertiliser units that recycle carbon and nitrogen on-site.

Smart cities and market outlook

The self-powered fertilisation research teams are mapping how CONFETI hardware can be integrated into smart cities, where waste streams, energy flows and food production converge at the neighbourhood level. The team envisions modular SMFCs buried beneath gardens and agricultural fields, paired with compact CO2 capture units. These units would feed decentralised fertiliser micro-reactors.

Through discussions with municipal utilities, urban tech companies and district energy operators, as well as presentations at specialised innovation forums, the team is identifying pilot sites and business models. These dialogues establish CONFETI technologies as practical tools for circular metabolism in the built environment.

Public engagement and knowledge transfer

CONFETI’s outreach project translates laboratory results into accessible narratives. Through a series of seminars, webinars and hands-on workshops, researchers have engaged with students, policymakers and industry leaders to clarify how carbon dioxide and nitrate can be repurposed as fertiliser precursors.

Digital campaigns extend this dialogue by distributing infographics and videos that track project milestones in real time. This combination of on-site and online engagement builds social licence and cultivates the partnerships that are essential for large-scale deployment.

Policy-ready ecodesign for low-impact urea

CONFETI uses life cycle thinking as the basis for ecodesign. In accordance with the Eco-Design for Sustainable Products Regulation (ESPR 2024/1781), the sustainability research team developed an ecodesign matrix with 15 criteria and 36 quantitative indicators. The matrix tracks technologies from raw material extraction through manufacturing, use and end-of-life. Partner workshops selected a subset of tailored criteria and indicators for each subsystem, based on measurability and functional influence. Data collection for full life cycle assessments (LCAs) is underway, and initial results have prompted revisions to ionic-liquid recipes and membrane processing to improve the environmental profile of the membranes.

The project also addresses the use of critical raw materials (CRMs) in the design of CONFETI technologies, in accordance with the Raw Materials Act (2024/1252). Since day one, partners have been advised on the classification of the materials used in the prototypes. Following the ecodesign matrix, the technologies will be monitored to ensure that CRMs are not used or that recyclability is ensured in the cases where viable substitutes are not found.

Knowledge protection and commercial pathways

CONFETI’s exploitation strategy is anchored in stringent intellectual property governance. Our investigators enforce the confidentiality clauses outlined in the grant and consortium agreements. It also maps patentable inventions on a rolling 12-month roadmap and secures them through filings listed on the European Commission’s Innovation Radar. Photoreactors and silk-based bioelectrodes are going to be protected, ensuring freedom to operate as prototypes advance.

Meanwhile, market scouting aligns technical milestones with sectors poised for rapid adoption. Target users include farmers and agrochemical suppliers seeking on-site nitrogen fertilisation, solar developers looking to monetise captured CO2, semiconductor fabrication plants demanding low-carbon ammonia, and municipalities interested in decentralised water treatment and energy recovery. This integrated IP-and-market approach maximises commercial traction when laboratory technologies are ready for scaling up.

From metrics to crops: looking ahead

In the first 12 months, CONFETI evolved from a concept into a connected chain of hardware, including solid-state membranes that absorb four milligrams of CO2 per gram, a flow cell that already sustains currents above 10 mA cm-2, a photocatalyst that converts nitrate

into ammonia using natural sunlight, and buried biobatteries whose steady output complements photovoltaic power. These components together embody the project’s founding premise: that circulating carbon and nitrogen pollution can be recaptured and redirected into fertiliser production with minimal fossil fuel usage.

The next phase will focus on system validation, further material optimisation and integration of components into pilot systems. By grounding every step in measured performance and life-cycle metrics, CONFETI is advancing toward a landscape in which urea is produced where and when needed with a fraction of the current environmental cost, transforming emissions into agronomic assets.

Credits from the following research groups and institutions

Universitat Autònoma de Barcelona (UAB)

Electrochemistry, Photochemistry and Organic Reactivity Group (GEFRO-UAB)

Computational BioNanoCat (UAB) Sostenipra (ICTA-UAB) Groups Parc de Recerca UAB (PRUAB)

Agencia Estatal Consejo Superior de Investigaciones Científicas (CSIC) GTQ Group

Universiteit Antwerpen (UANTWERPEN)

ELCAT Group

SOFTMAT Group

Centre National de la Recherche Scientifique (CNRS)

Université Paul Sabatier (UPS)

Arkyne Technologies SL (BIOO)

Centro de Investigaciones Energéticas Medioambientales y Tecnológicas-Ciema (CIEMAT) FQM374 Group

Iowa State University (ISU)

Vela Research Group

Project summary

The EIC-funded CONFETI project aims to develop innovative lab-scale technology that captures and converts CO2 and N2 from air or flue gases into urea using renewable energy, bypassing critical raw materials. It also plans to recycle nitrates into ammonia or urea through sunlight-driven photocatalytic technology, promoting a circular and sustainable carbon and nitrogen economy.

Project partners

Autonomous University of Barcelona (UAB), The Institute of Microelectronics of Barcelona (IMB-CNM-CSIC), Research Centre for Energy, Environment and Technology (CIEMAT), Bioo, the University of Antwerp (UANTWERPEN), University of Pisa (uniPi), French National Centre for Scientific Research (CNRS), University Toulouse III – Paul Sabatier (UPS) and Iowa State University (IOWA).

Project lead profile

Gonzalo Guirado is a full professor at the Universitat Autònoma de Barcelona, specialising in sustainable chemistry, including green valorisation of CO2. He has advised 18 PhD and 33 master’s theses, published over 105 peer-reviewed articles and holds three patents. He has coordinated or participated in over 32 research projects funded by European, national, regional, university and industrial sources.

Project contacts

Gonzalo Guirado

CONFETI Project Coordinator

Universitat Autònoma de Barcelona – UAB

Email: gonzalo.guirado@uab.cat

Virginia Mata Marcano

CONFETI Project Communication Manager

Parc de Recerca UAB – PRUAB

Email: Viginia.mata@uab.cat

Beatriz de la Rica Botella

CONFETI Project Communication Manager

Email: beatriz.delarica@uab.cat

Funding disclaimer

This project has been co–funded by The European Innovation Council (EIC) under the European Union’s Horizon Europe research and innovation programme – grant agreement number 101115182.

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the EIC. Neither the European Union nor the granting authority can be held responsible for them.