VegWaMus CirCrop is a project of Dr Agnieszka Jasinska under the Marie Skłodowska -Curie Individual Fellowship Action of the EU HORIZON 2020 research and innovation programme.

The project aimed to close the loop between combined dairy manure and food waste-based biogas production, mushroom and vegetable cultivation, and create a zero-waste cultivation system. Mushroom and plant crop cultivation is normally performed through energy- and resource-intensive processes (based on fossil and mineral resources) in specialised commercial operations such as climate-controlled tunnels and greenhouses. These operations generate wastes, and the CO2 footprint of the produce is high. The idea of the project appeared as a follow-up to another EU-founded project, Food to Waste to Food (F2W2F), where Dr Agnieszka Jasinska was one of the main researchers. The main task was to create and construct a bubble-insulated semi-closed greenhouse and integrate it with the biogas plant, where the digestate from the biogas production would be used as a substrate component for plants and organic fertiliser. The biogas plant would also feed the plant with CO2. When developing circular waste-based alternatives for horticulture, one must consider both the environmental impact of the material sources upstream and their reuse downstream. The challenge for mushroom and greenhouse production is the utilisation of the spent cultivation substrates (SCSs). SCS should not be a neglected waste but a resource for other connected activities. The new VegWaMus CirpCrop project is focused on mushroom and plant cultivation and waste substrate reuse.

The project consists of five work packages and different tasks:

- WP1 – Digestate utilisation

- WP2 – Mushroom cultivation

- WP3 – Spent cultivation substrate management

- WP4 – Monitoring mineral content of substrates and crop stability

- WP5 – Demonstration and dissemination.

As the project is in the final dissemination phase, the highlights of the projects are presented here.

WP1 – Digestate utilisation

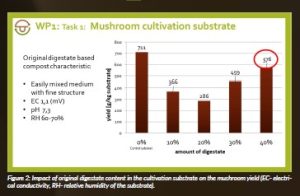

In WP1, the objective was to develop a fine and even, easily mixed substrate for upscaled mushroom cultivation. Mushroom cultivation substrate composition is based on the substrate’s dry matter (DM) content before processing. The digestate from anaerobic digestion (AD) of source-separated household food waste and dairy manure was used non-separated in its original form to avoid centrifuging. The original digestate (OD) was added to phase I substrate and further prepared according to commercial Agaricus production. Mixed substrate was composted and pasteurised in conditions mimicking the commercial process. Investigating the different amounts of digestate, the experiments showed that to obtain both an easily mixed medium with fine structure and good yields, the amount of digestate must be 40 per cent of the substrates DM (Figure 2).

WP2 – Mushroom cultivation

For the growing experiment, two Agaricus species, Agaricus subrufescens and Agaricus bisporus brown variety, were chosen for their high nitrogen content tolerance in the initial cultivation substrate, pest and disease resistance and higher DM content of fruiting bodies than common white button mushroom. Also, two oyster mushrooms, pink and yellow species (Pleurotus djamor and citrinopileatus), were researched and showed the best performance in terms of yield and fruiting bodies quality.

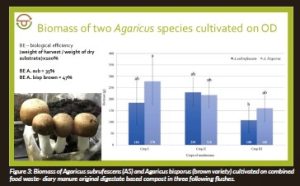

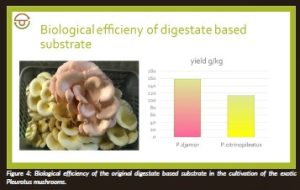

The biomass obtained on the experimental substrate differed between the two cultivated Agaricus species, A. subrufescens and A. bisporus (brown variety) and between the subsequent crops harvested (Figure 3). A. bisporus yielded better than A. subrufescens in the first harvest, in second flush A. subrufescens yielded better than A. bisporus, and the third flush was again better for A. bisporus (than for A. subrufescens. However, both species performed well on the OD-based substrate. The OD-based substrate performed well as a cultivation substrate showing high biological efficiency in the oyster mushroom cultivation, especially for two exotic species: pink and yellow oyster mushrooms. The biological efficiency of the substrate is an index that indicates the amount of the substrate conversion into fresh fruiting bodies (Figure 4).

WP3 – Spent cultivation substrate management

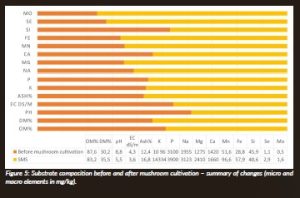

SCS is growing medium which stays after the cultivation of mushrooms (SMS) or vegetables (SGS) and for many years was considered a problematic waste product from farming. However, in the new transition to sustainable, circular farming systems, it is seen as a valuable product which could be recycled. WP3 focuses on decreasing the post cultivation wastes and reuse substrates by developing SCS management. SMS is characterised by high organic matter content and low bulk density and is high in soluble salts. The essential micro and macronutrient content increased significantly after mushroom cultivation. The pH after the cultivation of mushrooms dropped to 5.5, which is appropriate for most plant cultivation (Figure 5).

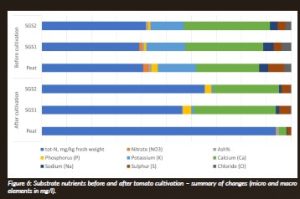

SGS has a good composting potential with a sufficiently high C/N ratio and organic matter content to heat up during composting. Alternatively, the SGS could be used directly for improving soil fertility in outdoor agriculture and landscaping (Figure 6). However, reusing growing media and crop wastes into new growing media represents a risk of disease and excessive levels of heavy metals and salts, especially when the original materials used are themselves organic wastes. To eliminate potential pests, and due to the high mineral salt content, it is recommended that the growing media be composted or co-composted with additional waste products, which will also amend the structure.

WP4 – Monitoring of crop stability

Monitoring of mineral circulation from substrate to mushroom and leftovers in the SMS was performed. The mineral content was analysed using inductively coupled plasma optical emission spectrometry (ICP-OES). The bioaccumulation of the minerals in mushroom crops was determined in the two Agaricus species. Bioaccumulation of elements in mushroom yields was evaluated. Over 45 elements were determined for the mushroom species. Thirty elements had BC over one, which indicates active accumulation in the fruiting bodies. BFC factor >1 indicates effective accumulation of selected elements. The analysis highlighted that the range in variation found for most elements was much larger in A. bisporus than that seen in A. subrufescens and followed a different hierarchical cluster. The order and sequence of BCF values for all elements and cropping differed among A. subrufescens and A. bisporus (Figure 7).

WP5 – Dissemination and demonstration

Finally, a start-up company SOPPAS emerged from the project itself. The start-up company SOPPAS aims to perform various mushroom cultivation on OD-based substrate in the container-based farm franchised locally to the farmers interested in the solution. The products will be repurchased and distributed fresh and dried to the end consumers in the locally grown food distribution chain. SOPPAS, based on the outcomes of the VWM CC project, will also engage several other products:

- SOPPSTRAT – plant growing substrate from SMS/SMC

- CUL(T) – Kit – cultivation kit for home mushroom growing

- CirCrop/CirSopp – know-how on the circular plant and mushroom cultivation

- BioSopp – processes mushroom products.

Find out more or follow the project

https://lindum.no/nyheter/forskningsprosjekter/vegwamus-circrop/

PROJECT SUMMARY

VegWaMus CirCrop aims to develop commercial mushroom and vegetable production into an integrated food-to-waste-to-food biosystem. The objective is to close the loop between food waste-based biogas production and reuse of the output after anaerobic digestion. Integrated mushroom cultivation is interesting from a circular approach; organic wastes are utilised for energy and crop production in a closed system.

PROJECT PARTNERS

VegWaMus CirCrop is based at the R&D department of Norwegian leader in waste treatment Lindum AS, University of Oslo (Norway) and Poznan University of Life Sciences (Poland). Reklima is a consortium of greenhouse growers (Veksthusgruppen), innovative greenhouse producer (BBBLS), waste treatment company (LindumAS) and biogas producer (GreveBiogas). In 2017 the consortium realised a large R&D greenhouse unit located next to a new large anaerobic digestion plant, The Magic Factory (Sem, Norway). SOPPAS is a start-up mushroom-producing company that emerged from the project as a follow-up action.

PROJECT LEAD PROFILE

Born in Poznan, Poland, Dr Agnieszka Jasinska received her doctorate in horticulture, edible and medicinal mushroom cultivation from Poznan University of Life Sciences in 2012. Since then, she has worked in academia and research tightly connected with a circular food-to-waste-to-food approach and zero-waste mushroom production. She received an MSC-IF grant in 2017 to develop commercial mushroom and vegetable production in an integrated food-to-waste-to-food biosystem. Dr Jasinska has authored over 40 peer-reviewed articles.

PROJECT CONTACTS

Agnieszka Jasińska

Lerpeveien 155, 3036 Drammen, Norway

+47 911 43 013

Poznan University of Life Sciences

- Wojska Polskiego 28, Poznan, Poland

agnieszka.jasinska@up.poznan.pl

FUNDING

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie Individual Fellowship (MGA MSCA-IF) grant agreement No. 751052.

Figure legends

Figure 1: Circular farming system from food waste to food.

Figure 2: Impact of original digestate content in the cultivation substrate on the mushroom yield (EC- electrical conductivity, RH- relative humidity of the substrate).

Figure 3. Biomass of Agaricus subrufescens (AS) and Agaricus bisporus (brown variety) cultivated on combined food waste- diary manure original digestate based compost in three following flushes.

Figure 4: Biological efficiency of the original digestate based substrate in the cultivation of the exotic Pleurotus mushrooms.

Figure 5: Substrate composition before and after mushroom cultivation – summary of changes (micro and and macro elements in mg/kg).

Figure 6 Substrate nutrients before and after tomato cultivation – summary of changes (micro and macro elements in mg/l).

Figure 7: Heat map and hierarchical cluster analysis (HCA) for bioaccumulation factor (BCF) for determined elements and harvesting (Crop 1, 2 and 3) for A. subrufescens and A. bisporus.

Figure 8: The structure of SOPPAS, the start-up company that emerged from the project.