The current critical situation in Europe and the world makes the importance of European countries’ own resources at all levels abundantly clear. Strong and reliable regional supply chains will play an essential role in the future of economic sovereignty, social security and stability in the countries of the EU. Short-distance supply chains are also critical for climate protection and resource efficiency, both now and in the future.

As some basic raw materials are unavailable in the EU, it is more challenging to establish short-distance supply chains for some materials. Wood products, however, offer the biggest potential for short-distance supply chains. It is important to remember that the European forest area has grown by about 9 per cent since 1990, reaching 277 million hectares—about 35 per cent of the total European region (FOREST EUROPE | Publications). Nevertheless, material flows and supply chains have now become global, even for wood products, with an upward trend. This not only results in massive climate impacts but also destroys established medium-sized structures and weakens value creation, especially in rural regions.

The LIFE Climate Value Chains project aims to change this and set the course in a different direction. The project raises awareness among key stakeholder groups about the importance of regional, short supply chains for climate and economy. By implementing and scaling the eco-label Holz von Hier® (HVH) as a best practice example and prooving climate-optimised value chains in the field of construction, housing and bioenergy are established, demand is promoted, especially in the public sector. This contributes to the European climate goals and supports regional European value chains. In non-German-speaking EU countries, HVH is implemented as Low Carbon Timber® (LCT).

Climate-optimised supply chains for sustainable building and living

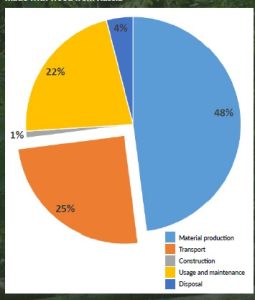

In the context of the New Green Deal, the building sector is a key pillar for CO2 reduction targets, as this is where a large proportion of resources and energy are consumed. So far, however, the focus has been on energy consumption in the use phase of buildings. However, as buildings become more energy-efficient in the use phase through savings in red energy, the share of the grey energy of the upstream chains of the building materials and products becomes more significant. Here, the origin of the raw materials and climate-optimised supply chains with the shortest possible routes play a key role. The project shows that truly sustainable construction cannot do without climate-optimised short supply chains. For example, transport-related emissions for a modern building can account for up to 25 per cent of the building’s emissions over its entire life cycle, including 60 years of use, demolition and disposal. Typically, however, designers and builders have almost no influence on the supply chains of building materials. With the introduction of HVH/LCT for building products, planners and public authorities have, for the first time, an effective tool to actively manage the ‘low carbon’ footprint of products and buildings.

Climate-optimised supply chains for bioenergy

Especially under the pressure of the current fossil fuel supply situation, a climate-friendly energy supply is becoming a central issue today. In this context, the upstream chains of the fuels must not be overlooked. In the EU, arithmetically, about 20–50 per cent of the wood residues, wood chips and pellets on the market are imported, depending on the assortment. Especially for short-lived energy materials, origin and shortest possible supply chains are key issues for real climate protection. In the field of bioenergy, LCT/HVH should therefore be established in the EU within the framework of the project as proof of sustainable biomass compliant with the RED regulation.

The climate- and environmental label Holz von Hier® respective Low Carbon Timber® as a best practice example

The proved climate and environmental label Holz von Hier® (HVH), or Low Carbon Timber® (LCT) in non-German-speaking countries, identifies wood products from sustainable forestry that have also been produced in above-average climate-friendly supply chains. The eco-label is based on scientific principles, addresses a key environmental factor and is externally monitored by neutral third parties. It uses an innovative electronic controlling system with real-time monitoring and operates independently of and across borders. LCT/HVH complies with the principles of the GHG Protocol and recognised financial standards and is compliant with ISO 14024, ISO 38200, EUTR, as well as the requirements of the RED III Regulation. It thus also represents a best practice demonstration for deforestation-free supply chains. Due to its conformity with the requirements of Directive 2014/24/EU, it can also be put out to tender. It offers public authorities an interesting perspective for the first time to combine climate protection and regional value creation and promote them via sustainable public procurement. By strictly tying the chain back to the forest, LCT/HVH strengthens the wood of domestic forest owners and European wood products against imports into the EU with sometimes significantly worse sustainability standards.

LCT/HVH environmental footprint and ECO footprint

The environmental impacts of the upstream chains of products used are currently recorded using classic life cycle assessment values, which are essentially based on the energy consumption of production. The quantitative and qualitative environmental impacts of raw material extraction have so far been insufficiently covered. In addition, transport in the entire ‘cradle-to-gate’ and ‘gate-to-customer’ supply chains has not yet been captured realistically in conventional life cycle assessment, which uses standard data sets for this purpose. Little can be said about climate and environmental balance at the construction site without proof of origin and supply chains. However, a system-generated environmental footprint of HVH/LCT certified products provides specific individual and product-related information on environmental impacts, including transport to the construction site.

In addition, an innovative ECO footprint is used for the first time to link quantitative environmental impacts, such as those specified in environmental product declarations, with important environmental impacts that can only be described qualitatively and to integrate them into the evaluation. Only in this way can a comprehensive picture of the environmental impact of specific products be created, which is also compatible with the requirements of the European PEF (product environmental footprint) initiative.

New European Institute for Low Carbon Circular Economy

As part of the project, a European Institute for Low Carbon Circular Economy will be established that will carry on the project results and extend the topic of climate-optimised and circular supply chains to other material groups to enable fair material comparisons.

The Institute aims to strengthen and ensure climate-optimised supply chains in the internal market and to contribute with scalable and practical best practice examples to bring the already existing good legal framework of the European sustainability and climate goals even further into practical implementation.

Participation opportunity

We would like to thank the EU commission, its bodies, and the LIFE programme for enabling the first best practice examples to be implemented with the project EU-LIFE-Climate Value Chains. Since climate-optimised supply chains are good for the climate and support the economic sovereignty of the countries and regions in the EU, we ask all responsible persons in the Commission and its bodies for ongoing dialogue and support.

The project is not a closed circle and restricted to certain partners or regions but invites all relevant stakeholders to participate and use the instruments and results right from this moment. Policymakers could integrate the instruments in national or regional strategies for climate protection, public authorities may use the environmental label and the provided instruments for green public procurement, and SMEs can immediately join the network and benefit from their product marketing. Feel free and contact us!

PROJECT SUMMARY

The project aims to initiate short-distance regional supply chains of timber products in the business sector and raise the demand for such products in several European countries. This will be achieved by implementing and extending the eco-label Holz von Hier® (or Low Carbon Timber® in non-German speaking countries) in value chains and raising awareness of the meaning and usability of certified products among private and public customers and professionals.

PROJECT PARTNERS

The project will be carried out in Germany, Austria and Luxemburg by the lead partner, Holz von Hier non-profit ltd. Additional partners are ENVIpark in Italy, the Business Support Centre Kranj and the Wood Industry Cluster in Slovenia.

PROJECT LEAD PROFILE

The project is led by the organisation Holz von Hier, holder of the same-named eco-label. Holz von Hier is an expert in sustainable supply chains, establishing a new eco-label for sustainable timber products and climate-friendly cross-border value chains. It is currently present in six European countries with a network of more than 250 companies using the tools and more than 100 partners at regional, national and international levels.

PROJECT CONTACTS

Project lead, Holz von Hier

Neuenreuth 24, 95473 Creußen, Germany.

Dr Gabriele Bruckner

Dr Philipp Strohmeier

+49 (0)9209 91897 51

info@holz-von-hier.de

www.holz-von-hier.eu

www.climate-value-chains.com

ENVIpark (Italy)

Luca Galeasso

+39 011 2257480

luca.galeasso@envipark.com

BSC Kranj (Slovenia)

Helena Cvenkel

+386 31 302 382

helena.cvenkel@bsc-kranj.si

Wood Industry Cluster (Slovenia)

Bernard Likaer

+386 1 5898 284

grozd@sloles.com

FUNDING

The LIFE Climate Value Chains project has received funding from the LIFE programme of the European Union under grant agreement No. LIFE20 CCM/DE/001665.

Image legends

Share of transport at the carbon balance of buildings made with wood from Russia.