Swarup Mahato, Researcher, Department of Mechanical and Production Engineering

Aarhus University

Martin Dalgaard Ulriksen, Associate Professor Department of Mechanical and Production Engi- neering, Aarhus University

Bilal Ali Qadri, R&D Vibration Engineer, Vestas Aircoil

Lasse Uhd Christensen, R&D Heat Exchanger Engineer, Vestas Aircoil

In part five of our ongoing series with the CP-Sens team, who are working to make digital twin technology a practical reality for SMEs, we turn our attention to the next phase in their journey: making sense of the data.

We spoke with researchers from Aarhus University, alongside Vestas Aircoil—who represent SMEs within the CP-Sens project—about their collaboration on algorithm development and testing.

All in the algorithm

Algorithms are a critical part of realising digital twins, enabling the translation of raw data into meaningful information that can be used to build or refine a digital model, interpreting data into actionable parameters. Martin Dalgaard Ulriksen, Associate Professor at Aarhus University’s Department of Mechanical and Production Engineering kicked off the interview with some background on what the teams are setting out to achieve: “We have the data, and based on that data, we want to say something about certain characteristics of the physical system we’re considering—what we call modal parameters.”

What modal parameters reveal about system behaviour

“When we have a physical system—say, a mechanical or structural system—we have some mass, some stiffness, and some damping, with the latter being the dissipation of energy,” explained Martin. “The combination of those three components can be condensed into some characteristic features that tell us something about the system. We refer to those as modal parameters.”

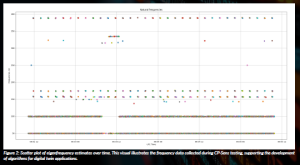

These include values like eigenfrequencies—the natural frequencies at which a structure tends to vibrate—and mode shapes, which describe the spatial deformation patterns when the system vibrates freely. “Those components, along with some characteristic damping, are what constitute the modal parameters,” he added.

Martin noted that these are widely used in structural health monitoring. “If you suddenly see a drop in eigenfrequency, then it could be due to structural damage or something similar.”

Modal parameters also enable model updating. They are used as signatures to calibrate mathematical models, allowing for predictive simulations such as forecasting how a charge air cooler—like those manufactured by Vestas Aircoil—might respond to different operational conditions. This helps ensure the digital model stays closely aligned with the behaviour of the real-world system it represents.

Building on existing methods

The CP-Sens team has focused on adapting and developing existing algorithmic approaches to suit SME use cases, rather than creating new methods from scratch. “We looked at existing methods—topics that are already well covered in the literature and industry—and made some incremental contributions, tweaking them for our specific purpose,” explained Martin. “There’s a strong focus on development—providing something usable within the project timeframe.”

The project’s algorithm development centres on four practical areas: system identification, model updating, virtual sensing and fatigue analysis—each adapted to meet the challenges SMEs face in implementing digital twin technology.

The development team and workflow

The overall concept is developed collaboratively, and implementation is handled by different members of the team depending on their area of focus. Postdoctoral researcher

Swarup Mahato and research assistant Jakob Vium Medom, both working in the Department of Mechanical and Production Engineering at Aarhus University, are doing the heavy lifting within this work package—implementing and testing the algorithms based on the team’s collaborative designs.

The work is shaped by ongoing discussions with project partners. “We have regular talks with Vestas Aircoil, as well other CP-Sens industry partners, about what features we all think should be in there, and then we try to accommodate that,” Martin added. “It’s a very flexible approach.”

Deep dive into algorithm components

The team has divided the algorithm development into four distinct areas, or ‘function blocks,’ to manage complexity. Each block targets a specific part of the digital twin process.

“System identification would be one block,” added Martin. “That’s about having some experimental data from which we estimate the modal parameters.”

“Model updating would be another block—we use those modal parameters to calibrate our mathematical models, so we can run predictive simulations with a model that’s sufficiently accurate and representative of the physical system.”

“Virtual sensing,” Martin explained, “is the task of trying to estimate something that you haven’t measured. That lets us infer values in locations where there aren’t physical sensors—so we get more data, without more hardware.”

Fatigue analysis forms the final block. “That’s about getting an overview of how long we would expect the system to be able to operate under the conditions they’re operating under,” Martin added.

From concept to code: implementing the function blocks

Each algorithm is developed as a separate function block—modular chunks of Python code, each focused on a specific part of the workflow. These can operate independently or be integrated into the broader Digital Twin as a Service platform (DTaas) developed in previous projects by colleagues at Aarhus University. The CP-Sens project expands on this research by adapting their algorithms and plugging them into the existing DTaaS platform.

“We’re preparing these like building blocks,” said Swarup. “Then we’re trying to make a kind of pipeline—feeding in the data from the Raspberry Pi and eventually seeing the outcome.”

Martin added that these blocks are being assembled in collaboration with colleagues across departments. “The function blocks we’re developing are glued together in the end in this digital twin as a service platform,” he said. “We provide the algorithms, and then colleagues here at the Department of Computer and Electrical Engineering, Aarhus University—Dr Prasad Talasila, Professor Peter Gorm Larsen, and a recent BEng graduate, Mohammed Ahmad Abdulkarim, plug them into the open source framework.”

Swarup highlighted the platform’s openness as a key strength: “It’s a general platform. It’s not just for one use case. Users can add their own function blocks to fit their system—whether it’s a heat exchanger, a cooler, or something else entirely.”

Collaborative development and real-world challenges

The CP-Sens team emphasises close collaboration between academic and industrial partners throughout algorithm development. While the academic team leads early-stage design and implementation, industry partners feed back on what features are needed in real-world environments.

Swarup noted that practical application often presents challenges that go far beyond typical academic exercises. “We spend a lot of time on academic problems,” he said. “When a real-world problem arises—like modelling a wind turbine—it’s really challenging. For some structures, it’s very complex, and that puts a lot of pressure on us.”

Martin reflected on the technical demands involved: “It’s very easy to cook up an algorithm that works on a clean dataset with very little noise. It’s much harder when the data comes from a real machine in a real setting.”

Despite the complexity, the team sees strong value in the exchange. “We get insights into challenges we would never think about otherwise,” Martin said. “It’s

almost always a positive thing when there’s collaboration between academia and industry. That’s one of the really valuable aspects of this collaboration—industry partners push us to think about things that aren’t usually part of our academic routines.”

Bilal Ali Qadri from Vestas Aircoil shared a similar perspective: “I’ve definitely learnt a lot from the team at Aarhus University, and that helps us to go back and do our job better… sometimes there’s something that we can immediately apply or change.”

Industry perspectives and practical application

The industry partners are already starting to apply the algorithms developed by the Aarhus team. Bilal said: “Our engine cooler is currently under test, continuously feeding real-time data into the system developed by Aarhus University.”

Lasse Christensen, also on the Vestas Aircoil team, anticipates further developments. “As more comprehensive data becomes available from ongoing tests, we look forward to leveraging the full potential of model updating,” he notes.

This work represents a relatively underexplored area. The application of advanced algorithmic techniques to charge air coolers is rarely, if at all, documented in existing literature, meaning the work has the potential to address a meaningful knowledge gap for similar SME manufacturers.

From development to deployment

The team sees this transition as a natural phase shift. Responsibility for development has largely sat with the university partners up to this point, but the focus is now shifting toward the industrial partners, who will begin applying the algorithms under production-like conditions. As these real-world applications progress, the academic teams will respond to evolving needs and technical refinements.

Swarup described this as building a pipeline—from data input, including sources such as the Raspberry Pi prototypes, through to usable algorithmic outputs—ensuring that each step of the process works reliably and cohesively in practice.

Open source advantage and scalability

The open source nature of what CP-Sens is developing significantly lowers entry barriers by removing the high upfront and recurring costs often associated with commercial software. This makes digital twins a much more accessible option for SMEs. Following on from their innovative approach to lowering costs associated with data collection, covered in our previous article, CP-Sens is making great progress in delivering on its objectives.

Educational and broader impact

Beyond technical gains, the team sees CP-Sens as a platform for inspiring future engineers. As Martin put it, “If this project gets students interested in things like digital twin modelling or system dynamics, then that’s fantastic.” He added that because the tools being developed are open source, they may find value well beyond the scope of the current project.

Testing in practice: challenges and next steps

The CP-Sens team remains mindful that practical implementation may surface new challenges as the project moves from prototyping into applied use. Martin noted, “We’re now in the phase where we’re testing what we’ve built. It’s at a stage where it works, but we need to test it in the real-world environment, and that might trigger improvements.”

He added that further refinements are likely to emerge as industrial partners begin applying the system under production-like conditions.

Open invitation to collaborate: get in touch

The team is keen to inspire similar collaborations and welcomes contact from organisations exploring related challenges. “It’s worth collaborating and talking about your problems and what you’re trying to achieve,” said Martin. “You never know what it might lead to. We’re open to different types of companies or people approaching us, not necessarily just the traditional test houses or manufacturers.”

If your organisation is grappling with similar challenges—or developing systems that could benefit from digital twin thinking—the CP-Sens team encourages you to get in touch.

Project summary

CP-Sens is working to make digital twin technology accessible to small and medium-sized enterprises (SMEs) in the mechanical and structural engineering sectors. The project is creating a user-friendly platform that combines sensors, simulation models and real-time data to create virtual replicas of physical systems. This technology allows SMEs to monitor, analyse and optimise their products and processes, leading to cost savings, faster innovation and improved efficiency.

Project partners

Aarhus University

Hottinger Brüel & Kjær (HBK)

Vestas Aircoil

Vienna Consulting Engineers (VCE) FORCE Technology

Project lead profile

CP-Sens is led by HBK and supported by researchers at Aarhus University, specifically in the: Department of Electrical and Computer Engineering; Department of Civil and Architectural Engineering; and Department of Mechanical and Production Engineering.

Project contact

Bilal Ali Qadri, MSc (Eng) PhD

R&D Vibration Engineer Vestas Aircoil

Smed Hansens Vej 13 6940 Lem, Denmark

Email: baq@vestas-aircoil.com

Funding

The work presented here is partially supported by the CP-SENS project funded within the Grand Solutions 2022 programme, Innovation Fund Denmark, under grant agreement No. 2081-00006B.

Figure legends

Figure 1: Control panel used in the Vestas Aircoil setup. This hardware forms part of the data acquisition environment supporting algorithm development and testing for digital twin applications.

Figure 2: Scatter plot of eigenfrequency estimates over time. This visual illustrates the frequency data collected during CP-Sens testing, supporting the development of algorithms for digital twin applications.