Dmitri Tcherniak, Senior Research Engineer, Hottinger Brüel & Kjær

Bilal Ali Qadri, R&D Vibration Engineer, Vestas Aircoil

Lasse Uhd Christensen, R&D Heat Exchanger Engineer, Vestas Aircoil

In part four of our ongoing series with the CP-Sens team—who are working to make digital twin technology a practical reality for SMEs—we explore one of their most quietly radical moves yet: cutting the cost of R&D without cutting corners.

One of the most promising developments? A surprisingly small, simple and cost-efficient piece of hardware: the Raspberry Pi.

We caught up with the team at Vestas Aircoil and Dmitri Tcherniak, Senior Research Engineer at Hottinger Brüel & Kjær (HBK), to understand how a single-board computer—originally designed for education—has become a practical tool in the early stage prototyping of digital twin systems.

Prototyping at a fraction of the cost

Dmitri started by introducing us to the Raspberry Pi: “It’s a single-board, very powerful computer developed in the UK—originally for education—and has a very low cost.”

The Raspberry Pi found a second life among engineers, developers and makers as a flexible and affordable tool for experimentation. “It opens a lot of opportunities for us—to play with, to experiment, to prototype—at a fraction of the cost of a commercial solution,” Dmitri said.

What’s in the setup?

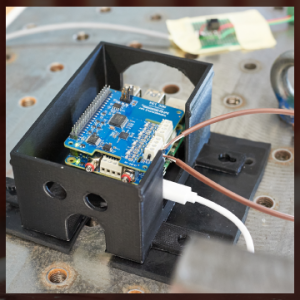

The Raspberry Pi is paired with a simple, entry-level data acquisition (DAQ) system that allows sensors to feed data into the board. Specifically, the team used the MCC 172 IEPE Measurement DAQ HAT. “It has two channels,” Dmitri explained. “That means we can connect two accelerometers, or two microphones—any two sensors that output voltage.”

He added that the system can be scaled up to accommodate more sensors, stacking multiple boards to increase the number of input channels. “When we talk about data acquisition, it’s normal to talk about the cost per channel—meaning, per sensor input,” explained Lasse Uhd Christensen from Vestas Aircoil. “It’s a way to compare systems.”

To put the potential impact into perspective, Dmitri compared the Raspberry Pi setup with HBK’s industry-leading equipment—used in final digital twin systems: “At HBK, we produce top-of-the-class equipment for measuring vibrations,” he said. “With Raspberry Pi, the cost per channel”—that is, per connected sensor—“is around ten times lower.”

He stressed that while HBK’s solutions are designed for critical, high-reliability applications, the Raspberry Pi offers an accessible way to experiment and test ideas in the early R&D phase—a crucial advantage for SMEs, who might otherwise be challenged to justify the cost of full-scale commercial deployment hardware.

The origin of the idea

Originally, HBK’s role in CP-Sens was to develop smart sensors tailored to specific digital twin applications. However, the team quickly realised that this approach wouldn’t scale across use cases.

“In the case of Vestas Aircoil, we would need a thermocouple and an accelerometer,” said Dmitri. “That means we’d have to develop two smart sensors. Some other digital twin might need a microphone—then we’d have to develop another smart sensor. It started making our job impossible.”

Instead, the team shifted to a more flexible solution: using standard analogue sensors combined with a simple DAQ system and Raspberry Pi for data processing. This setup could be adapted for different applications, making it ideal for SMEs.

When ‘good enough’ is the best fit

The team are careful not to overstate the Raspberry Pi’s role. It’s not a substitute for high-spec commercial systems in critical environments—but it doesn’t have to be. “The price drives the solution, not the quality,” said Dmitri. “If you want to put this data acquisition system in an aircraft or a submarine, it’s a very different story. But here, it’s not that critical. Good enough is enough.”

Lasse agreed: “We’re selling products all over the world, and we don’t want to deliver very expensive equipment to a site that’s very far away and run the risk of losing it. So there are a lot of reasons why this more cost-efficient setup makes sense.”

Real-world trials underway

Vestas Aircoil is currently replicating the Raspberry Pi setup in its lab and also has a more ‘proven’ solution ready for testing (Figure 2).

Bilal said: “So far, it works very well. We’re trying to connect everything and see if we can send the data live and ac- cess it live as well. We’re also preparing for a larger trial test at a specialist testing facility.”

Lasse added: “It’s a very nice solution. It doesn’t take up much space, and it’s clever because it also acts as a DAQ system and a computer. That means we can do some data treatment on-site before sending it to the cloud, which can make things faster and more efficient.”

This local processing—known as edge computing—has become increasingly valuable for digital twin applications that generate large volumes of data due to high sampling rates. “If the temperature is changing slowly, you don’t need many measurements per second,” explained Dmitri. “But with vibration, we’re talking about hundreds—thousands of measurements per second per channel. That’s a huge amount of data to transfer over the internet.”

Edge computing and intelligent filtering

By processing data closer to the source, the team can reduce the amount of information that needs to be transmitted. “We can perform spectral analysis right on the Raspberry Pi,” said Dmitri. “Instead of sending raw data, we send just the relevant frequencies.”

This kind of filtering is especially useful when trying to detect specific mechanical behaviours—like resonance. “We want to not go so conservative when it comes to designing our cooler,” said Bilal. “So we can do some predictive maintenance or optimise our cooler to avoid resonant frequencies. For example, if the engine runs at a fixed RPM and correlates with one of the resonant frequencies, some bad things happen to the cooler.”

Multi-physics monitoring

Unlike some CP-Sens partners who focus on vibration alone, Vestas Aircoil combines data from multiple sensor types to model how heat and movement interact in real-world conditions.

“There are huge temperature gradients,” said Lasse. “A cooler that is rectangular can sort of turn into a banana shape in real life because the temperature difference is so high.”

“One half of the cooler might be experiencing 230 °C, while the other is 50 °C,” added Bilal. “So we have huge stress. We’re trying to replicate that numerically—using real values instead of just simulation assumptions.”

This combination of sensor data feeds into the broader CP-Sens goal of creating digital twins that aren’t just visual replicas but simulation-driven models capable of predicting system behaviour. By combining data from both thermal and structural sensors—such as temperature and vibration—and using it in a single simulation, the team are creating what’s known as a multi-physics model: one that accounts for the interaction between different physical phenomena.

“We measure both temperature and vibration at the same time and try to correlate it in the same numerical model,” said Dmitri. “That becomes multi-physics.”

A flexible entry point—not a final product

The team are clear that the Raspberry Pi setup is a tool for experimentation—not a long-term solution. “We don’t expect Raspberry Pi to be part of the final commercial system,” said Dmitri. “The temperature range it can withstand isn’t right, and it’s not robust enough for industrial environments. But it’s perfect for proving the concept.”

He added that the concept could be adapted to more industrial-grade alternatives in future. “There are other single-board computers—Banana Pi, Orange Pi—that cost a bit more but are built for industrial use. So this is really about testing and de-risking before scaling.”

Looking ahead

As part of the CP-Sens project’s mission to support SMEs, the Raspberry Pi pilot is a clear example of how accessibility, flexibility and experimentation can help break down barriers to adopting advanced technology.

“We’re experimenting now,” said Lasse. “But in two months, we’ll have much more to share! It’s a promising start.”

New to this series?

We’ve been following the CP-Sens project through the lens of Vestas Aircoil, one of the project partners representing the needs of SMEs. CP-Sens seeks to break down barriers to realising digital twin technology, making it more accessible for SMEs. In earlier articles, we introduced the project’s aims, met the key partners and looked at some of the technical and organisational challenges they were working to overcome. Catch up here:

Breaking barriers to digital twin adoption: CP-Sens paves the way for SMEs

doi: 10.54050/PRJ2021840

From concept to reality: Vestas Aircoil’s approach to realising a digital twin

doi: 10.54050/PRJ22436

Securing digital twins: how CP-Sens is providing cybersecurity solutions for SMEs

doi: 10.54050/PRJ2222770

PROJECT NAME

CP-SENS – Cyber-Physical Sensing for Machinery and Structures

PROJECT SUMMARY

CP-Sens is working to make digital twin technology accessible to small and medium- sized enterprises (SMEs) in the mechanical and structural engineering sectors. The project is creating a user-friendly platform that combines sensors, simulation models and real-time data to create virtual replicas of physical systems. This technology allows SMEs to monitor, analyse and optimise their products and processes, leading to cost savings, faster innovation and improved efficiency.

PROJECT PARTNERS

Aarhus University

Hottinger Brüel & Kjær (HBK)

Vestas Aircoil

Vienna Consulting Engineers (VCE)

FORCE Technology

PROJECT LEAD PROFILE

CP-Sens is led by researchers at Aarhus University, specifically in the: Department of Electrical and Computer Engineering; Department of Civil and Architectural Engineering; and Department of Mechanical and Production Engineering.

PROJECT CONTACT

Bilal Ali Qadri

R&D Vibration Engineer, MSc(Eng) PhD.

Vestas Aircoil

Smed Hansens Vej 13, 6940 Lem, Denmark

Tel: +45 3138 6978

Email: baq@vestas-aircoil.com

FUNDING

The work presented here is partially supported by the CP-SENS project funded within the Grand Solutions 2022 programme, Innovation Fund Denmark, under grant agreement No. 2081-00006B.

Figure legends

Figure 1: Left – The Vestas Aircoil Raspberry Pi setup up, including the data acquisition system (MCC 172 IEPE Measurement DAQ HAT). Right – The Raspberry Pi connected to sensors.

Figure 2: Lasse and Bilal standing on either side of a Hioki datalogger.