What are the main problems targeted by the project?

The project stems from the urge to solve two problems affecting both human and environmental health: drinking water pollution by emerging contaminants (ECs).

Water is increasingly contaminated by chemicals, including molecules that affect public health, such as per- and polyfluoroalkyl substances (PFAS), heavy metals, drugs and dyes used in thousands of commercial products. Current technologies for the removal of ECs at point-of-use (POU), point-of-entry (POE) and centralised scale mainly rely on adapting existing and non-specific technologies, none of which is exhaustive in terms of efficiencies, costs and sustainability.

Plastic waste disposal and incineration and consequent CO2 production and air contamination by organic volatile compounds

The process used to assemble the membranes in a cartridge intrinsically originates fibre waste of high quality and value, being identical to the membrane integrated into the filters. However, due to the cutting process, the fibre waste cannot be further used to fabricate other hollow-fibre membranes (HFMs). The scraps need to be stored, transported and finally incinerated, which strongly impacts the whole ecosystem.

In this context, the LIFE REMEMBRANCE project was launched by Medica S.p.A., with CNR-ISOF’s support and the EU’s financial contribution through the LIFE programme.

Why the LIFE programme?

When LIFE REMEMBRANCE partners presented the proposal, they were fully aware that the members of such an innovative project could seek funding via other EU instruments (mainly H2020). However, they believed that the LIFE programme was the most suitable funding instrument because it:

- bridges the gap between research and market introduction of more sustainable chemical processes

- aims specifically at contributing to the shift towards a resource-efficient, low carbon and climate-resilient economy and to the protection and improvement of the quality of the environment in the EU and worldwide

- contributes to implementing, updating and developing European Union environmental policy and legislation, thereby contributing to sustainable development.

Medica S.p.A.

A leader in the production of electromedical equipment and single-use medical devices, with more than 50 registered patents and an innate vocation for research and development, Medica S.p.A., thanks to continuous technological innovation, is the only Italian company with hollow-fibre spinning technology for the purification of blood and water.

CNR ISOF

The National Research Council (CNR) is Italy’s largest public research institution. Its mission is to perform research in its own institutes, to promote innovation and competitiveness of the national industrial system, to promote the internationalisation of the national research system, to provide technologies and solutions to emerging public and private needs, to advise government and other public bodies and to contribute to the qualification of human resources.

The framework LIFE REMEMBRANCE’s topics

LIFE REMEMBRANCE tackles three main topics:

- Water

The adsorbent granules are used to remove contaminants from drinking water at centralised, POU and POE scale. LIFE REMEMBRANCE will make it possible to remove novel contaminants, including PFAS. - Waste

Polymeric waste generated during the production of HFMs (5–10 per cent in weight vs total annual output) is currently incinerated: LIFE REMEMBRANCE recycles them to produce HPG and cartridges. Moreover, by providing safe drinking water, LIFE REMEMBRANCE will also reduce the consumption of water in plastic bottles and the resulting waste. - Environment and health

PFAS intake through drinking water or food can lead to serious health effects, such as pregnancy complications, thyroid disease, high cholesterol, reduced response to vaccines, liver damage and kidney and testicular cancers. LIFE REMEMBRANCE will produce cartridges to provide safe drinking water and achieve up to 100 per cent removal of PFAS, significantly reducing associated health risks to citizens.

The European context

LIFE REMEMBRANCE targets two main EU priority areas:

- Circular economy and waste reduction

The project supports circular economy goals by recycling hollow-fibre membrane waste into water purification sorbents, avoiding incineration, reducing CO2 emissions and improving the entire process’s carbon footprint. Additionally, it boosts tap water consumption by improving purification technologies, reducing reliance on bottled water, and cutting plastic waste. - Health

LIFE REMEMBRANCE will reduce health issues related to toxic contaminants, providing safe drinking water to ~1M citizens.

What are the EU directives that the project responds to?

Within the previously-mentioned EU priority areas, LIFE REMEMBRANCE responds to three EU directives:

- Drinking Water Directive 2020/2184/EU

This directive responds to the increasing number of contaminants found in water sources and to the related need to provide safe drinking water to citizens. In this directive, new target contaminants and threshold limits have been added. - Water Directive 2000/60/EC

Promotes sustainable water use. - Directive on Energy Efficiency 2018/2002/EU

Aims to reduce energy consumption by 32.5 per cent by 2030.

What does the term ‘emerging contaminants’ mean?

ECs are chemicals increasingly found in our waters, ingredients of more than 350 000 products used for civil or industrial uses (e.g. household products, pharmaceuticals and personal care products, pesticides and additives) that end up through several pathways in our water bodies.

Standard purification technologies do not efficiently remove ECs; thus, they enter the environment, affecting aquatic and land ecosystems and have also been found in tap water (i.e. the case of PFAS in Veneto region, Italy).

Their effect on human health is unknown, but increasing evidence of their impact on the reproductive system, neurodevelopment delays and cancer has been reported in literature.

The specific aim of LIFE REMEMBRANCE project

The project aims to demonstrate a highly sustainable, novel and efficient process and technology based on secondary materials exploitation for the efficient removal of ECs that will benefit both the environment and human health.

The new process and technology will rethink the removal of pollutants by applying the circular economy model, which is based on waste materials reuse, by reducing the CO2 emission level in a novel sustainable industrial process based on a much lower energy-demanding process. Hence, the innovation introduced by the LIFE REMEMBRANCE project will have tremendous environmental and socioeconomic impacts at the EU and global levels. It will offer a real demonstration of a sustainability-driven industrial solution.

Project scope and objectives

The innovation in the LIFE REMEMBRANCE project lies in its method for recycling hollow-fibre membrane waste into high-performance granular sorbents (HPGs), instead of incinerating it. These granules combine filtration with adsorption properties to efficiently remove contaminants like PFAS from water. This approach transforms industrial waste into a valuable product, enabling a circular economy. Additionally, the granules’ scalability and adaptability for various water treatment applications (e.g. POU and centralised systems) represent a novel, sustainable alternative to energy-intensive and wasteful technologies like reverse osmosis.

The three main actions of the project

- Specific environmental goals

Reduction of emerging, persistent contaminants in water

Contaminants may include PFAS, pesticides, antibiotics, disinfection by-products and heavy metals. LIFE REMEMBRANCE aims to remove >99 per cent of the mixture of ECs from drinking water in real operating conditions. This will be achieved by exploiting: (i) a new family of sorbent materials deriving from re-evaluated Medica waste products and from the tailoring of a dedicated production line; (ii) the realisation of POU systems in selected sites; and (iii) the realisation of a pilot treatment system in the potabilisation plant treating water from Po river.Recovery and upcycling of high-value industrial waste

Polymeric HFMs are used worldwide for micro and ultrafiltration in biomedical (e.g. dialysis and apheresis treatment, i.e. extracorporeal blood purification) and water purification (removal of bacteria and viruses). Due to the production process, the fibre edges of each fibre bundle cannot be used for filter assembly; thus, they are considered plastic waste that must be disposed of and incinerated. Having such fibre edges identical in purity, composition and morphology to the fibre core length, LIFE REMEMBRANCE intends to recover and reuse the fibre edge scraps as precursors of sorbents for air and water purification.

Energy saving and emissions related to waste disposal

Combining the production of safer drinking water with the reduction of plastic waste derived from the HF scraps and from plastic bottles for human consumption and related incineration procedures with a high CO2 A high consumption of water bottle plastic is reported in the EU: in Italy in 2019, only 20 per cent of Europeans found drinking water outside of their home country acceptable, and 29 per cent of households do not trust tap water for drinking due to the reported negative effects on health. The European Commission estimated that providing high-quality drinking water could reduce bottle plastic waste consumption by 17 per cent. - Implementation actions

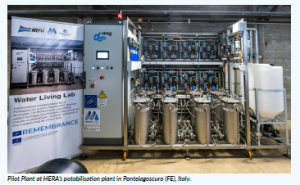

A pilot line has been started with both the partner (for the technology development) and a relevant end-user (for testing the technological solution in a real environment) and monitored. Also, a prototype of removing WWTP machinery (starting from different processing parameters) has been manufactured and tested. Finally, the pilot line will be assessed, fine-tuned and validated by relevant industrial stakeholders.

3. Monitoring of the impact of the project actions

- Relevant environmental indicators, i.e. energy and water consumption, chemicals emissions and retention (PFAS) are monitored throughout the entire action.

- A thorough life cycle assessment (LCA) is conducted to assess the project’s environmental impact by considering the entire value chain from raw materials to product disposal.

- A preliminary eco-toxicological assessment and preliminary market and socioeconomic analyses have been conducted.

- A clear statement about the ESG sustainability level of the project.

Technological innovation

The technological innovation in pills

The technology innovation in LIFE REMEMBRANCE involves recycling industrial hollow-fibre membrane waste into high-performance granular sorbents (HPGs). These granules exhibit adsorption properties, enabling the efficient removal of harmful water contaminants like PFAS. The process transforms waste into reusable materials, offering a scalable and energy-efficient alternative to conventional technologies, such as reverse osmosis, with zero water loss and lower environmental impact. The approach supports both sustainability and high-performance purification across various applications.

The technological innovation in detail

The innovative process used in the LIFE REMEMBRANCE pilot plants involves recycling hollow-fibre membrane waste into high-performance granular sorbents (HPGs). The process includes grinding to create uniform granules and sieving to ensure the proper size range. These granules, with high porosity, efficiently adsorb contaminants from water.

The granules are then integrated into custom prototype cartridges for testing in pilot plants. The process aims to optimise sorbent performance, scalability and environmental sustainability, offering an energy-efficient and low-maintenance alternative to conventional water treatment technologies.

Pilot plant’s importance

The pilot plants in the LIFE REMEMBRANCE project focus on testing and optimising the recycling process of hollow-fibre membrane waste into granular sorbents for water purification. They will evaluate the performance of these sorbents in real-world conditions, including their efficiency in removing PFAS, scalability of the production process, and their integration into different water treatment systems (POU, POE and centralised plants). Data gathered will inform the optimisation of the sorbents’ design, environmental impact and potential for large-scale implementation.

Deriving benefits for stakeholders

The LIFE REMEMBRANCE project provides benefits across the value chain.

- Manufacturers gain from reducing waste disposal costs by recycling hollow-fibre membrane scraps into valuable sorbents.

- Water treatment providers benefit from a more efficient and sustainable solution to remove contaminants like PFAS, offering lower energy use and reduced maintenance.

- Consumers enjoy safer drinking water with fewer chemicals and less plastic bottle consumption.

- Environmental impact is minimised, with reduced waste and CO2 Additionally, the project creates jobs and fosters innovation in water treatment and recycling technologies.

- New job opportunities are created in production, research, and business development, promoting industry growth and innovation.

Results and benefits

EU goals and priorities

LIFE REMEMBRANCE meets the EU Research and Innovation policy by providing a solution that answers the needs of sustainable water treatment, waste reduction and resource efficiency. It directly supports the EU’s goals for reducing plastic waste, minimising chemical contaminants in water, and promoting a circular economy.

By recycling membrane production waste into effective sorbents, the project not only addresses water pollution but also contributes to the reduction of CO2 emissions and plastic bottle consumption, aligning with the EU’s environmental and health priorities.

KPIs and figures

By the end of the project, several key performance indicators (KPIs) are expected to be met. These include the treatment of 6 million litres of water, with the granules achieving up to 100 per cent PFAS removal. Granule production will scale to 50 kg per day, with 18 000 POU cartridges produced annually. The project will recycle 3 tons of membrane waste during its duration and save 58.5 kl of water, 57 kWh of energy and 80 kg of CO2 emissions compared to conventional reverse osmosis. Additionally, it is forecast to prevent 224 kg of plastic bottles from being used.

Results from both the pilot plants

Test with a comparison of two materials (granular activated carbon and PSU-GO) without any spike for 6 weeks:

- Neither GACs nor PSU-GO scraps introduce any variability and fluctuations in the monitored parameters

- PSU-GO showed higher reductions, which were not statistically significant for aluminium and total PFAS.

Test with spike of 6 PFAS 1-day

- 6 PFAS have been continuously spiked into the plant over 6 hours of test

- Results demonstrated that PSU-GO performed better than GAC in the first hour

- The percentage removal of GAC reached and outperformed PSU-GO in the last part of the test

- The normalised adsorption capacity per gram of material showed better performance for PSU-GO than for GAC, especially considering the mass of only the GO present in PSU-GO. Thus, the amount of total PFAS adsorbed during the test was of 11.65 ng/g GO, 2.32 ng/g PSU-GO, 1.63 ng/g GAC

- The visual inspection of the materials after test showed a preferential distribution of PSU-GO in tank 2, probably contributing to preferential flows and not homogeneous contact between contaminants and adsorbent.

The impact

The impact from an ESG-based sustainability perspective

The secondary-based products resulting from LIFE Remembrance’s innovative circular process are widely demanded by many sectors, such as the water utilities and the wastewater treatment solutions providers, as well as the chemical industries which produce polluting side products such as perfluorochemicals and other relevant emerging compounds of concern from a health and safety perspective. The economic and market (both B2B and B2C) impact is set and realised in compliance with the ESG sustainability criteria.

The goals towards global sustainability improvements have been recognised and set as those shown in Figure 2.

Additionally, the envisaged LIFE REMEMBRANCE benefits are defined and monitored through a series of KPIs aligned with the EU targets of the LIFE programme, meeting at the same time the specific objectives of the programme, the European Industrial Strategy and the need of the global stakeholders from industry, academy and governance/ policymakers.

The impact from a KPIs quantitative perspective

LIFE Remembrance will show a clear differentiation between the ‘USE’ and ‘NONUSE’ scenarios for the LIFE REMEMBRANCE solutions in terms of:

- economic (from local to global territories) impact

- human health direct and indirect impact

- environmental impact (natural resources savings, bio-diversity protection effect)

- social impact (novel professional profiles, awareness) regarding the local and global geo-area requirements provides the following quantitative results.

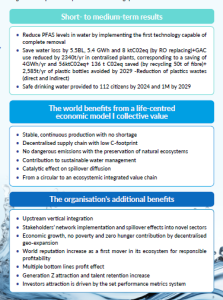

Short- to medium-term results

- Reduce PFAS levels in water by implementing the first technology capable of complete removal

- Save water loss by 5.5BL, 5.4 GWh and 8 ktC02eq (by RO replacing)+GAC use reduced by 2340t/yr in centralised plants, corresponding to a saving of 4GWh/yr and 56ktC02eq+ 136 t C02eq saved (by recycling 50t of fibre)+ 2,585t/yr of plastic bottles avoided by 2029 -Reduction of plastics wastes (direct and indirect)

- Safe drinking water provided to 112 citizens by 2024 and 1M by 2029

The world benefits from a life-centred economic model I collective value

- Stable, continuous production with no shortage

- Decentralised supply chain with low C-footprint

- No dangerous emissions with the preservation of natural ecosystems

- Contribution to sustainable water management

- Catalytic effect on spillover diffusion

- From a circular to an ecosystemic integrated value chain

The organisation’s additional benefits

- Upstream vertical integration

- Stakeholders’ network implementation and spillover effects into novel sectors

- Economic growth, no poverty and zero hunger contribution by decentralised geo-expansion

- World reputation increase as a first mover in its ecosystem for responsible profitability

- Multiple bottom lines profit effect

- Generation Z attraction and talent retention increase

- Investors attraction is driven by the set performance metrics system

LIFE REMEMBRANCE, in short

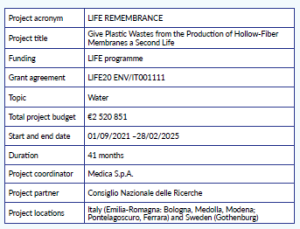

| Project acronym | LIFE REMEMBRANCE |

| Project title | Give Plastic Wastes from the Production of Hollow-Fiber Membranes a Second Life |

| Funding | LIFE programme |

| Grant agreement | LIFE20 ENV/IT001111 |

| Topic | Water |

| Total project budget | €2 520 851 |

| Start and end date | 01/09/2021 –28/02/2025 |

| Duration | 41 months |

| Project coordinator | Medica S.p.A. |

| Project partner | Consiglio Nazionale delle Ricerche |

| Project locations | Italy (Emilia-Romagna: Bologna, Medolla, Modena;

Pontelagoscuro, Ferrara) and Sweden (Gothenburg) |

For more information

Visit our website

Medica S.p.A.

Letizia Bocchi, PhD

Laboratory & IP Manager

Alberto Goldoni

Sales & Marketing – Water Division

alberto.goldoni@medica-spa.com

Giulia Santamaria

Communications Manager

giulia.santamaria@medica-spa.com

Consiglio Nazionale

delle Ricerche

Manuela Melucci, PhD

Senior Researcher

PROJECT NAME

LIFE REMEMBRANCE – Give plastic wastes from the production of hollow fiber membranes a second life

PROJECT SUMMARY

LIFE REMEMBRANCE’s ambition is a demonstrated circular production process of safe and innovative granules and cartridges for drinking water purification from emerging contaminants. The objectives will be achieved through the development of a novel technology based on the recycling of high-value industrial waste derived from hollow fibre membranes (HFM) filter production and validated with the collaboration of an internationally recognised utility company.

PROJECT PARTNERS

LIFE REMEMBRANCE counts on an academic and industrial partnership formed by Consiglio Nazionale delle Ricerche (CNR), CNR ISOF Department (Bologna), specialised in materials characterisation and water treatment technology validation, and Medica SpA, operating in the sector of disposable medical devices, hollow fibre membranes and filters for blood and water purification, always on the global market with innovative solutions and technologies.

PROJECT LEAD PROFILE

Dr PhD Letizia Bocchi received her PhD in Biochemistry, Biotechnology and Molecular Biology at the Università degli Studi di Ferrara. Employed in Medica R&D from 2010, her main achievements can be summarised in inventive activity (relevant patents about filtering membranes for multisectoral applications from biomedical devices to water management), set-up of cutting-edge laboratory dedicated to filters performance characterisation in vitro, set-up and successful upkeeping of a deep scientific cooperation with CNR- ISOF; Coordinator of GRAPHIL which participates to the Graphene Flagship. Bocchi is coauthor of 18 peer-reviewed scientific publications ranging from biotechnology to advanced materials topics.

FUNDING

The LIFE REMEMBRANCE project has received funding from the LIFE programme of the European Union under grant agreement No. LIFE20 ENV/IT001001.