Claus Ibsen, Group R&D Director, Vestas Aircoil

Bilal Ali Qadri, R&D Vibration Engineer, Vestas Aircoil

Lasse Uhd Christensen, R&D Heat Exchanger Engineer, Vestas Aircoil

In the previous edition of The Project Repository Journal, we explored CP-Sens, a project dedicated to making digital twin technology accessible to small and medium-sized enterprises (SMEs). Digital twins are virtual replicas of physical structures that enable companies to monitor, analyse and optimise their operations in real time. CP-Sens seeks to eliminate the barriers that deter SMEs from adopting this technology, such as high costs and complex implementation processes.

Vestas Aircoil specialises in designing and manufacturing heat exchangers for industrial applications and is a partner in the CP-Sens project. Although they are a smaller large enterprise (LE), Vestas Aircoil effectively represents SMEs within the project. The company has been developing a cooler to serve as the foundation for its digital twin, significantly advancing ongoing efforts to refine and enhance its products.

We spoke with the team at Vestas Aircoil to discuss the initial stages of developing their digital twin. This phase focuses on building and preparing the physical counterpart to gather data that will enhance the accuracy of its digital counterpart. As they navigate these challenges, their work exemplifies the CP-Sens mission, serving as a model for other SMEs.

Moving from concept to execution

Over nearly two years, Vestas Aircoil has meticulously designed a cooler that is not only functional but also optimised for data collection—an essential step in creating an accurate digital twin. “The overall goal with this cooler is to gain accurate digital models,” explains Bilal. “We want to measure something physical to update the virtual part. That’s the main goal.”

This task involves engineering precision and innovative thinking, but the team adhered to the ‘Keep it Simple Stupid’ (KISS) principle. The cooler must endure operational stresses while equipped with critical data collection sensors. “We made a conscious effort to simplify wherever we could. At one point, we had something like 60 sensors. We found ways to cut that down significantly, remove unnecessary complexity, and minimise our impact on the cooler’s performance,” Claus said.

The team’s key focus has been ensuring that the digital twin will accurately reflect how the cooler behaves in real-world conditions. To do this, they’ve paid close attention to what are known as ‘boundary conditions’—how the cooler is fixed in place and how these constraints affect its expansion when heated. They use a method called finite element method (FEM) to digitally simulate these physical conditions. As Bilal put it, “We need to get the digital model to behave the same way as the real thing, especially when it’s exposed to heat and stress. If our model doesn’t match what’s happening in reality, it won’t be very useful.” This real-world alignment is essential for creating a reliable digital twin.

Sensor configuration

The environment inside the cooler presents significant challenges for sensor placement. As Claus explained, “The airstream where the heat exchanger is placed can reach almost 200 °C and three bar pressure. It’s not a place you want to expose electronic components to, so we had to find a way to safely route the sensor wires outside without damaging the cooler.” This meant that the data logger for data acquisition had to be strategically placed outside the harsh internal environment to ensure it could function correctly and provide accurate data.

Given these constraints, Lasse was key to ensuring the sensors were correctly installed. “My role was to ensure the correct placement and installation of the sensors, communicating with our workshop contacts to ensure the work was carried out meticulously. We had to ensure that these sensors would accurately capture the data we needed,” Lasse explained. This careful consideration was essential, as the team needed to ensure the sensors function properly despite the challenging conditions.

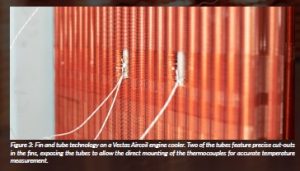

The cooler is equipped with 20 sensors in total. The 18 thermocouples were strategically placed to monitor heat development inside and around the cooler, mapping local temperatures to identify areas of thermal stress. “If everything is at the same temperature (uniform), there are no stresses. Minimising thermal stress is important, as it can lead to material bending or the initiation of cracks, which is important to be able to account for in our digital models. Furthermore, we are investigating methods to measure the temperature directly on the material, which is new to us. We have made cutouts in the fins to realise this.” noted Claus.

The two accelerometers will detect vibrations and potential anomalies. “In the future, we want to utilise accelerometer data to predict and identify potential faults in the tubes, enabling proactive maintenance and reducing downtime,” Bilal explained.

The choice to use 18 thermocouples and two accelerometers was influenced by cost, time constraints and specific data needs. “Thermocouples are relatively inexpensive and easy to mount, making them ideal for widespread temperature monitoring,” said Lasse. “In contrast, accelerometers are more costly, so their placement was carefully chosen to maximise the information we want to gain.”

Adapting the cooler for sensor integration

The cooler’s design includes a series of tubes that carry the heat-exchanging fluids. These tubes are surrounded by fins, which increase the surface area for more effective heat transfer. One of the key challenges was how to place the thermocouples in direct contact with the cooler’s tubes to measure the temperature accurately. “We had to make cuts in the fins surrounding the tubes to position the thermocouples directly on the material,” Claus explained. “This was new to us and required careful planning to ensure the modifications didn’t compromise the cooler’s performance.”

The process of making these modifications was not without its challenges, particularly in communicating the precise needs to the production team. “We had to speak to the production team multiple times to explain that this wasn’t just about cutting the fins—it needed to be done precisely and with care,” Claus noted. “The fins are crucial for the cooler’s efficiency, so any changes had to be handled with great attention to detail.”

Data collection

A crucial aspect of the CP-Sens project is data collection, which is set to take place after the cooler’s installation at a specialist testing facility. This facility houses a large two-stroke marine engine—larger than an average delivery van—providing a real-world environment to test the cooler.

Testing in such a real-world setting is indispensable for verifying the performance of the digital twin. “The data collected from these tests will be invaluable in refining our models and improving our numerical simulations’ accuracy,” says Bilal.

Challenges and lessons

The project highlights the complexities and challenges of realising a digital twin, an achievement that few companies have yet accomplished. As Bilal noted, “Many in the industry have what they call a digital twin, but it’s often more of a digital shadow—a model that lacks real-time data integration and the ability to mirror the physical object’s behaviour accurately.”

“What we’re doing is actually creating a digital twin with continuous data input and a dynamic model that reflects the real-world performance of the cooler,” added Claus.

Implementing an emerging technology has not been without its challenges. In addition to sensor placement, the team encountered various challenges during this phase of the project.

Communication was critical, especially when working with the production site, to convey the precise requirements for cutting fins to accommodate the sensors.

Then, there was the simple need to adapt. “None of us in the R&D are experts in setting up internal orders and making bills of materials. So that has been a learning curve,” laughs Claus.

The team have also been focusing on cybersecurity and efficient data handling. Ensuring that the data collected is securely transmitted and stored is crucial, especially when collaborating with external partners. “There is a lot to consider when you’re installing something at a third party because we don’t want our equipment to be a way in for hackers,” explained Lasse. This aspect will be explored in more detail in future articles.

Looking ahead

The work undertaken by Vestas Aircoil within the CP-Sens project is just the beginning of an exciting journey. As the cooler begins its testing phase, the team hope to gather valuable data to refine their digital twin.

“The idea of seeing our cooler come to life in a digital form and knowing it can change how we approach maintenance and efficiency is incredibly motivating,” explained Claus.

Bilal added, “The exciting part for me is the challenge of creating a digital twin for a complex structure like a heat exchanger. Replicating the physical behaviour of such a structure in a numerical model is something I have been deeply interested in and want to explore further.”

“What excites me is even getting the data! It’s exciting for me to gather the data we’ve talked about and planned for so long,” said Lasse.

And this is just the beginning. Claus concluded, “Then there are the other projects that we have started as a result of developing this cooler, where we have also been mounting sensors and so on. We have a lot of projects going on at the moment regarding sensor placement, digital twin data transfer, and more. So, it’s an exciting future. Realising that we have five or six future projects was a nice revelation!”

We wish Vestas Aircoil all the best with the data collection and refining their digital models. The next time we catch up with the team, we’ll explore cybersecurity— how the team has prepared to securely handle and transmit the vast amounts of data that digital twins rely on.

Follow Vestas Aircoil and the CP-Sens project on LinkedIn for the latest project updates as they happen.

Terminology

The Vestas Aircoil team agreed to simplify the terminology throughout this article to ensure their message is accessible to the widest audience possible.

Experts in the digital twin community will recognise that the work described aligns more closely with the concept of a ‘digital shadow’.

Digital twin: a virtual replica of a physical object that can alter the behaviour of its physical counterpart through real-time data integration.

Digital shadow: a subset of digital twin technology that focuses on creating a dynamic model reflecting the real-world performance of the physical object without altering its behaviour.

Project name

CP-SENS – Cyber-Physical Sensing for Machinery and Structures

Project summary

CP-Sens is working to make digital twin technology accessible to small and medium-sized enterprises (SMEs) in the mechanical and structural engineering sectors. The project is creating a user-friendly platform that combines sensors, simulation models and real-time data to create virtual replicas of physical systems. This technology allows SMEs to monitor, analyse and optimise their products and processes, leading to cost savings, faster innovation and improved efficiency.

Project partners

Aarhus University, Hottinger Brüel & Kjær (HBK), Vestas Aircoil, Vienna Consulting Engineers (VCE) and FORCE Technology.

Project lead profile

CP-Sens is led by researchers at Aarhus University, specifically in the: Department of Electrical and Computer Engineering; Department of Civil and Architectural Engineering; and Department of Mechanical and Production Engineering.

Project contacts

Bilal Ali Qadri

R&D Vibration Engineer, MSc(Eng) PhD.

Vestas Aircoil

Smed Hansens Vej 13, 6940 Lem, Denmark

Tel: +45 3138 6978

Email: baq@vestas-aircoil.com

Funding

The work presented here is partially supported by the CP-SENS project funded within the Grand Solutions 2022 programme, Innovation Fund Denmark, under grant agreement No. 2081-00006B.