Prof. Diego Misseroni and the S-FOAM team, Univerisità degli Studi di Trento

Technological advances in electronics and artificial intelligence are quickly improving how humans interact with wearable devices and robots. Soon, smart clothing connected to smartphones and other devices will monitor health metrics like heartbeat and insulin levels, and humanoid robots will help with work and household tasks. These innovations demand new design strategies to enhance material functionality, such as adapting to human movements, gently handling fragile objects and navigating tight spaces with robot arms. The ERC Consolidator Grant project S-FOAM—Self-Foldable Origami-Architected Metamaterials—aims to meet this need by designing materials that self-adapt to their surroundings without relying on sophisticated electronics or closed-loop controls.

Moving beyond folded paper to cutting-edge structures and metamaterials

The intricacies of folded flat surfaces and their resulting tessellations derived from origami art, observed in nature or discovered by serendipity and detailed observation, have become a source of inspiration over time. Origami has moved beyond being merely decorative and crafted objects to leading a technological revolution in the creation of devices for space applications at the macro-scale and the human body at the micro-scale. Various engineering fields have embraced the rise of the origami concept in envisioning and developing highly performative structures and metamaterials at multiple scales, applied in space, energy absorption, solar panels, biotechnology and soft robotics prototypes (Misseroni et al., 2024).

Their inherent capacity to transform from a foldable to a deployable configuration is due to the kinematic and deformation mechanisms proper from the origami geometry, dictated by the mountain and valley creases assignments enclosing the panels. This transition from a folded to an unfolded state has enabled the creation of both simple and sophisticated devices. For example, objects inspired by the traditional Miura-ori patterns, such as folded traveller maps for pockets or deploying mechanisms for satellite flyer units (Miura, 1985). A high level of foldability is a characteristic that allows for the fabrication of reconfigurable structures, which can be packed into compact shapes for easy transport, saving space and then be unfolded or set up in a different location. A current example that exploits this property is the optimised transportation of the primary mirror of NASA’s James Webb Space Telescope, made up of tessellating hexagons that can be folded or unfolded as needed once in space (Irion, 2010). Another example is the design of temporary and inflatable shelters, which can also be used in emergencies (Melancon et al., 2021).

Furthermore, the foldability attributed to origami patterns has been used in adaptive shading components for the Al Bahr Towers (Attia, 2017) and in prototypes of kinetic façades with shape memory alloys. These types of façades aim to achieve visual and thermal comfort along with energy efficiency (Pesenti, Masera and Fiorito, 2018). Therefore, they also represent an alternative for sustainable and resilient infrastructure.

Moreover, origami metamaterials have been developed by tailoring the stiffness of the panels and of the respective mountain and valley creases. For instance, a negative and tunable Poisson ratio can be achieved (Misseroni et al., 2022), as well as self-locking and a high strength-to-weight ratio. Certain cylindrical origami patterns, such as Kresling, complement high foldability with tunable levels of stiffness (Zang et al., 2024). Multi-stability is also achieved at specific geometrical proportions in terms of height and radius. This characteristic enables the creation of high-precision soft robotic arms that mimic the actions of artificial hands (Jiang et al., 2023). On the other hand, mono-stable and quasi-zero stiffness configurations can be obtained to create damping and high energy absorption devices, useful for landing components of drones (Yasuda et al., 2019).

Regarding meso- and micro-scale applications, these also require miniaturisation along with a high packaging capacity. Consequently, several researchers have proposed the development of more precise microgrippers (Leong et al., 2009) and drug delivery devices oriented towards robotic surgery being inspired by origami structures (Ghosh et al., 2017). Expanding the origami potential in biomedical engineering, deployable implants for the vertebral column have been envisioned to promote bone regeneration after a fracture through a minimally invasive process (Bobbert et al., 2020).

Transforming paper craft into reality

Bringing the origami concept to real-life applications involves transitioning from prototyped folded paper models to the fabrication of structures using a variety of highly resistant materials, from metals to polymers. In this context, the effectiveness of the folding mechanisms depends on the precise design of the mountain and valley creases, which function as actual hinges. For this reason, a wide range of complex systems have been proposed and adapted, including bolts, bars and pneumatic systems. While these resources have been successfully employed on a large scale, their applicability diminishes in smaller-scale contexts, particularly in biomedical devices for surgical operations, diagnosis and drug delivery.

The kirigami concept, which includes precise cutting in addition to folding, is a complementary strategy used to enhance the foldability of creases, especially in origami structures made from a single material. By reducing the stiffness of the panels, mountains and valley creases, kirigami increases flexibility and facilitates the folding-deployment process. Nowadays, kirigami is considered a promising approach for creating highly innovative reconfigurable 2D and 3D micro- and nanostructures using mechanical stress or ion-beam radiation stimuli (Chen et al., 2020).

Groundbreaking 3D printing and laser cutting manufacturing techniques have reduced the difficulty, manual labour and time required for fabricating complex patterns and tessellations in origami and kirigami, even at the micro-scale. These techniques also expand the range of materials that can be used, including reinforced and recycled polymeric filaments, reusable metal powders and photopolymers. As a result, the experimental phase must update testing protocols to validate the performance of the origami inspired devices, considering both the mechanical properties of novel materials and the technological limitations of the manufacturing processes.

What are the current challenges in origami inspired metamaterials?

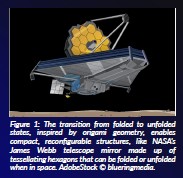

Origami patterns have significantly influenced the development of metamaterials, although most structures rely on predetermined folding lines and active mechanisms like pneumatic or electromagnetic actuators to fold and unfold. These mechanisms complicate the fabrication process and increase energy consumption.

The S-FOAM project aims to address these limitations by integrating the principles of origami and kirigami to create self-foldable materials that morph in response to external stimuli. Unlike traditional origami-based metamaterials, S-FOAM designs do not have predetermined folding lines. Instead, they react and fold differently to various stimuli without needing sophisticated electronics. This new approach leverages the concept of geometrical frustration and introduces defects by design to change the geometry of the microstructure, maximising their ability to adapt to changing environmental conditions and resulting in materials with enhanced mechanical properties.

This capability introduces new challenges and opportunities in the mechanics of solids and structures, enabling materials to optimise their stiffness, strength, toughness and environmental resilience.

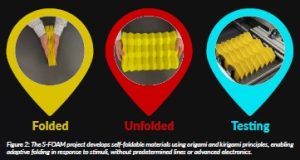

Applications of S-FOAM include soft robotics, where grippers can handle objects gently, and wearable devices that adapt to human movements. The project’s multidisciplinary approach involves analytical modelling, numerical simulation and proof-of-concept experiments, offering endless possibilities for reconfigurable devices without complex actuation mechanisms.

Moreover, S-FOAM’s design principles are valuable for developing adaptive medical devices and maximising solar power intake through flexible photovoltaic (PV) panels that change shape with the Sun’s movement. For example, metamaterials with flexible PVs can be used on building façades to optimise solar power intake throughout the day, supporting the shift from fossil fuels to renewable energy sources and helping to meet the EU’s Green Deal and the Paris Climate Agreement goals for decarbonised buildings by 2050.

They can also be incorporated into smart wearable devices that adapt to activities like walking or jogging, and into medical devices for precise, less invasive procedures like autonomous surgical grippers. S-FOAM promises a long-term impact by developing self-foldable materials with tunable mechanical properties for various applications, including soft robotics and wearable devices. Its interdisciplinary approach will also enhance scientific and technological knowledge in fields such as mechanical and civil engineering, dynamic and wave propagation control, and energy harvesting and clean energy transition.

References

Attia, S. (2017) ‘Evaluation of adaptive facades: The case study of Al Bahr Towers in the UAE’, QScience Connect, 2017(2), 6. doi: 10.5339/connect.2017.qgbc.6.

Bobbert, F.S.L., Janbaz, S., van Manen, T., Li, Y. and Zadpoor, A.A. (2020) ‘Russian doll deployable meta-implants: Fusion of kirigami, origami, and multi-stability’, Materials & Design, 191, 108624. doi: 10.1016/j.matdes.2020.108624.

Chen, S., Chen, J., Zhang, X., Li, Z.-Y. and Li, J. (2020) ‘Kirigami/origami: unfolding the new regime of advanced 3D microfabrication/nanofabrication with “folding”’, Light: Science & Applications, 9, 75. doi: 10.1038/s41377-020-0309-9.

Ghosh, A., Yoon, C., Ongaro, F., Scheggi, S., Selaru, F.M., Misra, S. and Gracias, D.H. (2017) ‘Stimuli-responsive soft untethered grippers for drug delivery and robotic surgery’, Frontiers in Mechanical Engineering, 3, p. 7. doi: 10.3389/fmech.2017.00007.

Irion, R. (2010) ‘Origami observatory’, Scientific American, 303(4), pp. 48–55. doi: 10.1038/scientificamerican1010-48.

Jiang, Y., Li, Y., Liu, K., Zhang, H., Xin, T., Chen, D., Wang, L. and Paik, J. (2023) ‘Ultra-tunable bistable structures for universal robotic applications’, Cell Reports Physical Science, 4(5), p. 101365. doi: 10.1016/j.xcrp.2023.101365.

Leong, T.G., Randall, C.L., Benson, B.R., Bassik, N., Stern, G.M. and Gracias, D.H. (2009) ‘Tetherless thermobiochemically actuated microgrippers’, Proceedings of the National Academy of Sciences, 106(3), pp. 703–708. doi: 10.1073/pnas.0807698106.

Melancon, D., Gorissen, B., García-Mora, C.J., Hoberman, C. and Bertoldi, K. (2021) ‘Multistable inflatable origami structures at the metre scale’, Nature, 592(7855), pp. 545–550. doi: 10.1038/s41586-021-03407-4.

Misseroni, D., Pratapa, P.P., Liu, K. and Paulino, G.H. (2022) ‘Experimental realization of tunable Poisson’s ratio in deployable origami metamaterials’, Extreme Mechanics Letters, 53, 101685. doi: 10.1016/j.eml.2022.101685.

Misseroni, D., Pratapa, P.P., Liu, K., Kresling, B., Chen, Y., Daraio, C. and Paulino, G.H. (2024) ‘Origami engineering’, Nature Reviews Methods Primers, 4(1), p. 40. doi: 10.1038/s43586-024-00313-7.

Miura, K. (1985) The method of packaging and deployment of large membranes in space. Technical Report IAF-80-A31. Tokyo: The Institute of Space and Astronautical Science.

Pesenti, M., Masera, G. and Fiorito, F. (2018) ‘Exploration of adaptive origami shading concepts through integrated dynamic simulations’, Journal of Architectural Engineering, 24(4), 04018022. doi: 10.1061/(ASCE)AE.1943-5568.0000323.

Yasuda, H., Miyazawa, Y., Charalampidis, E.G., Chong, C., Kevrekidis, P.G. and Yang, J. (2019) ‘Origami-based impact mitigation via rarefaction solitary wave creation’, Science Advances, 5(5), eaau2835. doi: 10.1126/sciadv.aau2835.

Zang, S., Misseroni, D., Zhao, T. and Paulino, G.H. (2024) ‘Kresling origami mechanics explained: Experiments and theory’, Journal of the Mechanics and Physics of Solids, 188, 105630. doi: 10.1016/j.jmps.2024.105630.

Project name

Self-Foldable Origami-Architected Metamaterials (S-FOAM)

Project summary

The S-FOAM project aims to enhance metamaterial design by integrating origami/kirigami techniques into cellular structures, allowing for self-foldability and shape-morphing in response to stimuli. This research seeks to optimise material stiffness, strength and resilience. Potential applications include soft robotics, wearable devices, adaptive medical devices and flexible solar panels that adjust their shape according to sunlight.

Project partners

Anandaroop Lahiri is a postdoctoral fellow with a PhD in Solid Mechanics from IIT Madras, specialising in origami-inspired metamaterials. Samantha Mora is a postdoctoral fellow with a PhD in Civil, Environmental and Mechanical Engineering from the University of Trento, focusing on 3D-printed, tunable, origami-inspired structures. Guozhan Xia, a postdoctoral fellow with a PhD in Solid Mechanics from Zhejiang University, specialised in nonlinear analysis, instability in soft electroactive plates, and advanced metamaterial behaviour. Shuhong Wang is a PhD student with an MS from Chongqing University, researching origami-inspired metamaterials. Joao Pedro Norenberg, a visiting PhD student from Sao Paulo State University, studies origami-inspired metamaterials for energy harvesting.

Project lead profile

Diego Misseroni is a Professor of Space Structures at the University of Trento, Italy, with a PhD in Structural and Solid Mechanics (2013). He has been a Marie Curie researcher and a Fulbright visiting scientist. His numerous awards include the 2024 ASME Young Investigator Award, ERC Consolidator Grant, 2022 EML Young Investigator Award, Fulbright fellowship, 2022 Zwick Roell Science Award, Paul Roell Medal and 2017 AIMETA Junior Prize. His research spans architected materials, metamaterials, origami engineering, flexible structures, buckling phenomena, and structural instabilities.

Project contacts

Diego Misseroni

Email: diego.misseroni@unitn.it

ORCID: orcid.org/0000-0002-7375-671X

LinkedIn: diego-misseroni-6b106811b/

Instagram: diegomisseroni/

Funding

This project has received funding from the European Research Council (ERC) under the European Union’s Horizon Europe research and innovation programme under grant agreement No. 101086644.

Figure legends

Figure 1: The transition from folded to unfolded states, inspired by origami geometry, enables compact, reconfigurable structures, like NASA’s James Webb telescope mirror made up of tessellating hexagons that can be folded or unfolded when in space. AdobeStock ©blueringmedia.

Figure 2: The S-FOAM project develops self-foldable materials using origami and kirigami principles, enabling adaptive folding in response to stimuli, without predetermined lines or advanced electronics.

Figure 3: The S-FOAM project develops self-foldable materials using origami and kirigami principles, enabling adaptive folding in response to stimuli, without predetermined lines or advanced electronics.

Figure 4: Potential applications of the S-FOAM project.