The EU LIFE-financed project LIFE RE-Fertilize has demonstrated the Aqua2N-process in an operational environment. The process has been proven to remove and recover 95 per cent of the ammonium nitrogen in sludge liquor at wastewater treatment plants, increasing the capacity of the plants and significantly reducing their nitrous oxide emissions.

The challenge with nitrogen

Nitrogen is essential to life and is among the nutrients consumed in the largest quantities by all agricultural crops. However, today’s linear flow of nutrients (nitrogen, phosphorus and potassium), from fertilizer manufacturing to wastewater treatment plant (WWTP) via food production and human consumption, is not sustainable.

Humans and animals excrete a significant fraction of the nutrients contained in the food they ingest. Alongside other agricultural sources, these nutrients find their way back into the environment primarily as municipal wastewater effluents. Anthropogenic loading of nutrients is the main cause of the eutrophication of receiving water bodies. Therefore, WWTPs are needed for treating these nutrient-rich effluents.

Both the manufacturing of mineral nitrogen fertilizers and the biological methods for wastewater treatment consume large amounts of energy and chemicals. They also lead to ammonia and greenhouse gas emissions, causing acidification and eutrophication.

The nitrogen treatment process in, for example, WWTPs requires massive aeration to oxidize all ammonium to nitrate. An expensive carbon source such as methanol is usually needed to obtain an efficient conversion of nitrate to nitrogen gas by denitrification. The biological process is both costly and sensitive to disruption. It also entails emissions of nitrous oxide, a powerful greenhouse gas which has an impact on the climate that is 300 times greater than carbon dioxide. Nitrous oxide emissions are, in fact, the largest climate impact for a WWTP.

Traditional methods of purifying nitrogen usually release it back into the air instead of recycling it. Ammonia, the basic compound for the production of nitrogen fertilizers, is by far the largest contributor to the carbon footprint in cereal production. The ammonia production industry for manufacturing mineral fertilizers relies heavily on natural gas as a non-renewable precursor for hydrogen and energy. Recycling the ammonia removed from wastewater streams can reduce the need to produce virgin ammonia.

What we want to achieve

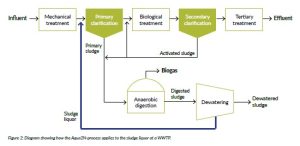

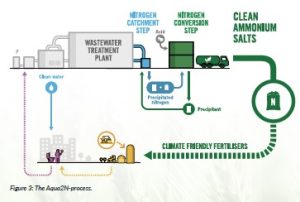

The LIFE RE-Fertilize project tackles the problem by removing and recovering nitrogen from liquid waste streams, such as sludge liquor from digested sludge in WWTPs and leachate water from landfills. For WWTPs having digestion of their sewage sludge, the sludge liquor flow is only 0.5–1.5 per cent of the total flow in the WWTP, but it stands for 15–30 per cent of the nitrogen load. Therefore, it is an important flow on which to apply nitrogen removal.

Removing the nitrogen from the sludge liquor in the WWTP with Aqua2N results in the following positive effects:

- reduced nitrogen load with >15 per cent in the main flow, making it possible to either

- connect more people to the existing WWTP, since nitrogen is often the limiting factor

- reduce the nitrogen levels in the effluent from the WWTP

- reduce the need for nitrogen removal (saving energy and carbon source additive) in the main flow

- reduced nitrous oxide emission with >15 per cent for the WWTP

- recovery of >15 per cent of the nitrogen in a supply, e.g. agriculture as fertilizer.

LIFE RE-Fertilize project objectives

The project’s overall goal was to demonstrate a new, innovative removal and recovery process for ammonium nitrogen, which produces a nitrogen product suitable for use in society, e.g. as fertilizer.

The project contained the following sub-objectives:

- validate the recycling process by upscaling from lab scale to pilot

- validate the market potential for the process and the product produced

- present and disseminate the project’s results to problem owners in Europe.

Achievements and results

Process validation and demonstration

The Aqua2N-process is a two-step process. In the first step, the ammonium nitrogen is caught with a precipitation chemical. The precipitated nitrogen enters after separation from the treated water—the conversion step. In the conversion step, acid is added to regenerate the precipitant, which is led back to the catchment step, and to produce the ammonium salt. The process is patented by EasyMining. The LIFE RE-Fertilize project used sulphuric acid; hence ammonium sulphate was produced. It is for this acid and ammonium salt that the process has been validated.

A demonstration plant was built to validate the process. The plant has been running at leachate water at Ragn-Sells’ waste handling plant Högbytorp outside Stockholm, Sweden, and at BIOFOS’ WWTP Lynetten in Copenhagen, Denmark. The demonstration plant has a capacity of 4 m3 incoming water per hour and is built to run in three different modes on two different applications. The leachate application and sludge liquor application differ both in ammonium nitrogen (NH4-N) concentration and composition, with sludge liquor having approximately four times higher NH4-N concentration than leachate. The leachate is a more complicated water to handle, which was known before starting the project.

In the LIFE RE-Fertilize project, the Aqua2N process has been taken from the technology readiness level (TRL) 3/4 to TRL 7. A continuous removal rate of 95 per cent has been proven at Lynetten WWTP in Denmark. During the demonstration run in spring 2022 at Högbytorp waste management plant (leachate application), challenges with running the process continuously were encountered due to the plant design not being optimal. Some changes were made to the plant when moving from the leachate application to the sludge liquor application; the plant was then able to run with good continuity. These valuable learnings for plant design were considered when establishing the conceptual design. Despite the demonstration plant encountering design-related challenges at the leachate application, great potential for the process to be applied at leachate is still evident.

With the results and learnings from the demonstration, a conceptual design for a plant with a capacity of 10 m3/h has been established. The conceptual design includes a:

- proof of concept

- design basis for different engineering disciplines

- process flow diagram

- mass- and energy balance

- cost estimate -30/+50 per cent.

Process validation achievements:

- Aqua2N-process is demonstrated in operational environment (TRL 7)

- 370 m3 leachate treated

- 1 144 m3 sludge liquor treated

- Conceptual design for the process established

Product validation

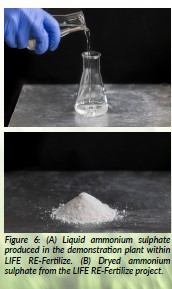

The first step within the project was to decide what product to produce. Ammonium sulphate was seen to be the most attractive option when considering the market for the product, the production process and the cost aspect. The product from the process is liquid ammonium sulphate.

It was important to validate the agronomic effects in comparison to conventionally produced ammonium sulphate. A pot trial test was conducted at the Swedish University of Agricultural Science (SLU) with liquid and solid products from both the leachate and the sludge liquor applications. The tests showed that the recovered ammonium sulphate had similar agronomic effects as conventional ammonium sulphate. This was expected since the composition is the same. The pot trials were carried out on spring wheat and spring rape seed.

In addition to product samples used for the pot trials, product samples have been provided to potential customers for evaluation and potential partners for up-concentration and granulation of the product.

The vast majority of the ammonium sulphate produced in the project has been supplied to farmers located close to the different application areas. The supplied ammonium sulphate will be used as a fertilizer together with slurry from biogas production and mixed with other nitrogen fertilizers and plant protection.

Compliance with the European fertilizer product regulation (FPR) has been essential to the project. The product produced from leachate application and wastewater application fulfils the requirement in the FPR regarding quality, such as contaminations. However, in the beginning LIFE RE-Fertilize, the product from both applications was hindered by the FPR due to origin. With the new FPR entering into force in summer 2022, the product from the sludge liquor in WWTPs is approved but still not for the leachate application. This is one of the reasons why the roll-out of the Aqua2N-process will focus on the sludge liquor application to start with.

Product validation achievements:

- 90 m3 ammonium sulphate (11 per cent) produced

- Pot trials validated similar agronomic effects as conventional ammonium sulphate

- Samples sent to six potential customers for evaluation

- End of waste conducted for the product

- Data sheet for the product established.

Market validation

The market for the Aqua2N-process is large. As part of the project, a business plan for the process has been established, including market analysis. The decision to focus on WWTPs in the first phase of the roll-out has been taken. The customer segment in focus is WWTPs with digestion of their sewage sludge, producing an ammonium nitrogen-rich sludge liquor when dewatering the digested sludge.

In Europe, there are about 2 800 biogas plants with sewage sludge as feedstock. The requirement for nitrogen removal differs between regions. Markets in focus at the beginning of the roll-out will be the Nordics, Benelux, Germany, Austria, Switzerland and Great Britain. The size of the WWTPs differs, which is why it is important to be able to scale the process up and down.

There is also a market for the Aqua2N-process outside Europe. Even though the focus currently is on the European market, the project and the process have been presented to other markets, e.g. at a conference held by the Asian Development Bank.

An important task in the project was to validate that the process is efficient and competitive. The conceptual design, including the results and learnings from the demonstration runs, has proven that the Aqua2N-process is competitive and efficient compared to nitrogen removal and nitrogen production today.

Highlights for market validation

The customer segment in focus for roll out of the Aqua2N-process is wastewater treatment plants with digestion of the sewage sludge.

The Aqua2N-process is proven to be competitive and efficient in relation to current nitrogen removal and production technologies.

Dissemination

Communication regarding the project has focussed on reaching potential customers, both for the Aqua2N-process and for the ammonium sulphate product. The project has been presented at industry conferences and exhibitions, such as International Water Association (IWA) World Water Congress in September 2022, NORDIWA in 2021, Berlin Klärschlamm Konferenz in 2022, ESPC4 in 2020 and IFAT 2022. Several visits to the demonstration plant took place in 2022; over 200 stakeholders, such as potential customers for the process and the ammonium sulphate, visited the plant.

The project has also been presented at conferences focussing on climate and sustainable innovation, such as COP26, COP27 and Nordic Circular Summit 2020. Dissemination strongly emphasised the importance of seeing wastewater treatment plants as resource plants. An opinion piece, “From wastewater treatment plants to resource plants”, has been published by the Swedish water industry association Svenskt Vatten, EasyMining and Ragn-Sells.

A lot of effort has also been put into highlighting the importance of making legislation circular. Today’s legislation often hinders the use of recycled, good-quality resources due to their origin. At the beginning of the LIFE RE-Fertilize project, this was the case for the product being produced in the Aqua2N-process.

Even though the product is of good quality, it was not allowed in the European FPR. Advocacy work has been conducted in Brussels by meeting politicians and experts, raising the question at COP conferences and a number of events, e.g. within Ragn-Sells’ cooperation with the WeDontHaveTime-organisation. Since summer 2022, the product from the wastewater treatment application has been approved in the new fertilizer regulation!

Values added by the Aqua2N-process

- Prevention of eutrophication

- Circular solution—keeping the removed nitrogen in a form that can be used in society again

- Reduction of nitrous oxide emissions

- Resource and energy efficient

- Cost-efficient.

Way forward

The Aqua2N-process has been demonstrated in an operational environment in the LIFE RE-Fertilize project. However, optimisation of the process is possible. In the first half of 2023, the focus will be on optimising the process and evaluating the possibility of splitting the two steps, the catchment step and the conversion step, into two separate plants.

At the same time, the commercialisation of the Aqua2N-process will start, presenting the results to potential customers who showed interest in the process during the LIFE RE-Fertilize duration. The ambition is to have the first commercial contract for an Aqua2N-plant in late 2023. Work on commercialising the ammonium sulphate product will also continue.

As highlighted in the market validation, the market potential for the Aqua2N-process is huge, and the interest from the market is large. By rolling out the Aqua2N-process, significant value can be achieved by the wastewater treatment plant in increasing capacity, reducing nitrous oxide emissions and offering agriculture a recycled ammonium sulphate. The roll-out of this process will be positive both for the climate and for moving towards a sustainable society.

Project information

Project name

LIFE RE-Fertilize

(Identification number: LIFE18 ENV/SE/000265)

Cost and funding

The budget for the project was in total €3.63 m, of which €1.86 m was requested as an EU contribution.

Duration

July 2019 – December 2022

(Project was extended by 6 months)

Contact details

Anna Lundbom, Project leader

Partners

EasyMining is a Swedish innovation company within the Ragn-Sells Group. The company develops patented processes for recovering valuable materials from waste flows. It offers a range of solutions that help solve some of today’s most critical problems relating to the recovery of nutrients.

BIOFOS is Denmark’s largest wastewater treatment utility, treating wastewater from 1.4 million population equivalents in three plants around Copenhagen. The company has a strong focus on the reuse and recovery of valuable resources in wastewater.

Lantmännen is an agricultural cooperative and Northern Europe’s leader in agriculture, machinery, bioenergy and food products. With grain at the heart of their operations, they refine arable land resources to make farming thrive. Lantmännen is founded on the knowledge and values acquired through generations of farmers.

Ragn-Sells is a privately held corporate group operating companies in four countries. We collect, treat, detoxify and recycle waste and residual products from businesses, organisations and households.

Project name

RE-Fertilize

Project summary

The overall goal of the RE-Fertilize project was to demonstrate a new removal and recovery process for nitrogen, producing a nitrogen product suitable for fertilizers, for example.

In the project, a demonstration plant for the process has been built, and the process has been demonstrated in operational environment with a removal rate of >95% of the ammonium nitrogen. The produced ammonium sulphate has been evaluated and its agronomic effect proven. A conceptual design has been conducted within the project, as well as establishing a business case, business model and business plan for commercialising the process and product.

Project partners

EasyMining is an innovation company developing and commercialising processes for recovering valuable materials.

BIOFOS is Denmark’s largest wastewater treatment utility, treating wastewater from 1.4 million population equivalents in three plants around Copenhagen.

Lantmännen is an agricultural cooperative and Northern Europe’s leader in agriculture, machinery, bioenergy and food products.

Ragn-Sells is a private company collecting and treating waste in four countries.

Project contacts

Anna Lundbom

Project leader RE-Fertilize

Funding

The LIFE RE-Fertilize project has received funding from the LIFE programme of the European Union under grant agreement No. LIFE18 ENV/SE/000265).

Figure legends

Figure 1: Today’s linear flow for nitrogen.

Figure 2: Diagram showing how the Aqua2N-process applies to the sludge liquor at a WWTP.

Figure 3: The Aqua2N-process.

Figure 4: (A) Inauguration of the demonstration plant at Ragn-Sells’ waste management plant Högbytorp— leachate application. (B) Inauguration of the demonstration plant at BIOFOS’ wastewater treatment plant Lynetten (sludge liqour application).

Figure 5: (A) Inside the bottom module where the reactions for both the catchment and the conversion steps take place. (B) Inside the top module where the separation for all steps is conducted with decanter centrifuges.

Figure 6: (A) Liquid ammonium sulphate produced in the demonstration plant within LIFE RE-Fertilize. (B) Dryed ammonium sulphate from the LIFE RE-Fertilize project.

Figure 7: Pot trials at SLU validated similar agronomic effects as conventional ammonium sulphate.

Figure 8: First delivery of ammonium sulphate produced at Lynetten WWTP to a farmer outside Copenhagen.

Quotes

“From measuring nitrous oxide emissions over some years, we have learnt that the nitrous oxide emissions in the main flow increases when nitrogen load peaks and the bacteria get overloaded. Removing the nitrogen in the sludge liquor should therefore reduce the nitrous oxide emissions to a larger extent than the reduction of the nitrogen load. For Lynetten, the nitrogen load from the sludge liquor is 15 per cent, if removing that we would reduce the nitrous oxide emissions with >15 per cent.”

Dines Thornberg, Development manager, BIOFOS.

“We see great potential in recovered ammonium sulphate from the Aqua2N-process and will continue to cooperate with EasyMining regarding this product after finalisation of the LIFE RE-Fertilize-project.”

Pär-Johan Lööf, R&D Manager Agri at Lantmännen.

“The international exchange is very important and the Aqua2N-process is interesting around the world – in the OECD countries there are both treatment plants and increasing treatment requirements.”

Anders Finnson, Senior Environmental Advisor at Svenskt Vatten and member of the reference group for the LIFE RE-Fertilize-project.

“If we are serious about creating a sustainable society, we have to start using the resources we already have produced over and over again. The Aqua2N-process is one solution for nitrogen recovery, which also has a positive effect on the climate since reducing nitrous oxide emissions significantly.”

Anna Lundbom, Project leader LIFE RE-Fertilize at EasyMining