The progressive substitution of consumer plastic products from fossil fuels is crucial to decarbonise our society (Tilsted et al., 2023).

This transition mandates the establishment of bio-based plastic value chains that offer both environmental sustainability and cost competitiveness. Although a range of bio-based polymers currently exists, their utility is often constrained by insufficient recyclability and/or a lack of biodegradability. Moreover, promising bioplastics continue to face technical hurdles that constrain their effective industrial scale-up (Ghasemlou et al., 2024; Rosenow et al., 2025).

One of the most promising bio-based and biodegradable polymers is the polyhydroxyalkanoates (PHAs) family. They are 100% biodegradable and synthetised by microorganisms from renewable carbon sources (Rosenow et al., 2025). Within the PHAs family, the PHBV (poly (3-hydroxybutyrate-co-3-hydroxyvalerate)) copolymer has excellent properties (demonstrated biodegradation in all environments, nontoxic, flexibility-modulated through 3HV content, mechanical resistance) for food packaging applications (Mai et al., 2024).

Despite the considerable research interest and potential attributed to poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), its widespread commercialisation remains constrained by several key factors:

- High production costs. These costs stem from multiple aspects:

- Elevated feedstock expenses, which can constitute more than 40% of total production costs (Simó-Cabrera et al., 2024).

- The synthesis of PHBV with high 3-hydroxyvalerate (3HV) content (>10 3HV%), desirable for flexible applications, typically requires costly precursors (generally volatile fatty acids) for most microbial producers. Consequently, commercially available PHBV grades generally exhibit a low 3HV content (typically <2%), significantly limiting their inherent flexibility potential (Ningbo Tianan Biomaterials Co. Ltd, no date; Rosenow et al., 2025).

- Conventional yields are low-medium and need high energy and investment costs at an industrial scale (Simó-Cabrera et al., 2024).

- Downstream processing for PHBV purification and recovery is generally complex, expensive, and can pose environmental challenges (Abate et al., 2024).

- Challenges in processability and property retention. PHBV exhibits a narrow processing window and a slow nucleation rate from the melt, complicating conventional thermoplastic processing and potentially leading to a loss of mechanical properties. While specific combinations of additives and other bio-based materials can improve certain properties, these approaches may be detrimental to the biodegradability, which means that a balance between both sides should be considered (Jin et al., 2023; Rosenow et al., 2025).

- Limitations in achieving the required flexibility for applications. Although PHBV with high 3HV content is promising for flexible uses, the low 3HV content in commercial materials (<2%) results in insufficient intrinsic flexibility for many applications. To achieve the necessary performance in semiflexible and flexible products (e.g. films, thermoformed sheets, textiles), PHBV is frequently blended with other flexible biopolyesters such as PBS, PBSA or PBAT. These formulations often contain a low PHBV proportion, which can compromise the overall biodegradability profile compared to pure PHBV (Rosenow et al., 2025).

ViSS solution: from agrifood industrial residues to high-performance food packaging

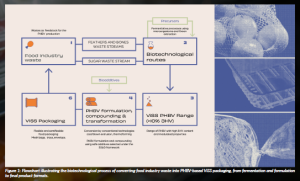

Funded by the European Commission, the ViSS project aims to establish a safe and sustainable value chain for PHBV, from food industrial residues to high-performance food packaging. This initiative focuses on valorising food processing residues as feedstock for the cost-effective production of high-3HV PHBV (15–30%) using extremophilic microorganisms and innovative green downstream processes. The project rigorously addresses technical challenges by developing processable and stable PHBV formulations with non-hazardous additives, creating flexible PHBV compounds and validating the material’s inherent suitability for mechanical recycling alongside its robust biodegradability. Furthermore, ViSS integrates a comprehensive safe and sustainable by design (SSbD) approach across its entire value chain, ensuring the safety of the developed materials and food packaging products, and analysing their economic, environmental and social sustainability.

In the long term, ViSS will contribute to increasing European industrial sustainability, competitiveness and resource independence by increasing bioplastic production capacities, while enhancing environmental and health benefits and fostering the widespread adoption of bio-based plastics value chains.

Sustainable production of high-3HV PHBV (15–30% 3HV)

ViSS proposes an integrated solution designed to overcome these aforementioned challenges through a multi-faceted strategy:

- We utilise an innovative and cost-effective combination of residual biomass streams as feedstocks. This comprises sugar wastes from the sweetening industry as a source of carbon, poultry residues as a source of nitrogen and phosphorus, and volatile fatty acids produced via biotechnological conversion of sugar wastes as precursors.

- Extremophilic microorganisms are employed for the production of ViSS PHBV, enabling the synthesis of polymers with tunable 3HV content. The inherent robustness of these organisms permits fermentation under non-sterile conditions, thereby circumventing the requirement for expensive stainless-steel infrastructure commonly necessitated by conventional bioprocesses and facilitating the use of lower-cost, plastic-based reactors.

- Implementation of novel, environmentally benign downstream processing techniques for efficient and sustainable PHBV extraction and purification.

Enhanced processability and formulation stability

The ViSS approach incorporates selected multifunctional additives into the PHBV formulation. These additives are non-hazardous and are specifically chosen to improve processability and material stability without compromising the inherent excellent biodegradability of the PHBV polymer.

A range of flexible materials is achieved through optimised PHBV-based blends. This strategy is designed to impart the necessary mechanical flexibility for target applications while crucially retaining the advantageous intrinsic properties of PHBV, including its robust biodegradability in relevant environments, bio-based origin and demonstrated non-toxicity. To support these purposes and avoid resorting to a very large-scale trial of numerous variants, the project integrates simulation modelling to predict the strength of an interaction between the additives and the PHBV.

ViSS will bring an important advance beyond the state of the art through the development of three types of safe, sustainable, biodegradable, and recyclable packaging based on PHBV: flexible, semiflexible and mesh bio-based formats. These packages are designed under ecodesign criteria and are intended to be safe and biodegradable in all environments, serving as a substitute for current fossil-based counterparts. In particular, ViSS is focused on developing mesh bags for fruits and vegetables, as well as trays, films and bags for fruits, vegetables and apiculture products.

Integrated safe and sustainable by design (SSbD) approach

ViSS is developing and implementing its entire value chain according to an innovative SSbD framework. The framework is composed of a design phase and an assessment phase that are applied iteratively as data becomes available.

This holistic approach is designed to ensure safety, environmental and economic performance across the products’ lifecycle, while simultaneously generating the necessary data, tools and framework conditions needed to foster increased social readiness and facilitate the market uptake of ViSS-based materials.

References

Abate, T., Amabile, C., Muñoz, R., Chianese, S. and Musmarra, D. (2024) ‘Polyhydroxyalkanoate recovery overview: properties, characterisations, and extraction strategies’, Chemosphere, 356, p. 141950. doi: 10.1016/j.chemosphere.2024.141950.

Ghasemlou, M., Barrow, C.J. and Adhikari, B. (2024) ‘The future of bioplastics in food packaging: An industrial perspective’, Food Packaging and Shelf Life, 43, p. 101279. doi: 10.1016/j.fpsl.2024.101279

Jin, A., Del Valle, L.J. and Puiggalí, J. (2023) ‘Copolymers and blends based on 3-hydroxybutyrate and 3-hydroxyvalerate units’, International Journal of Molecular Sciences, 24, p. 17250. doi: 10.3390/ijms242417250.

Mai, J., Kockler, K., Parisi, E., Chan, C.M., Pratt, S. and Laycock, B. (2024) ‘Synthesis and physical properties of polyhydroxyalkanoate (PHA)-based block copolymers: A review’. International Journal of Biological Macromolecules, 263, 130204. doi: 10.1016/j.ijbiomac.2024.130204.

Ningbo Tianan Biomaterials Co. Ltd (no date) ENMAT series, Available at: http://www.tianan-enmat.com/col.jsp?id=117

Rosenow, P., Fernández-Ayuso, C., López-García, P. and Minguez-Enkovaara, L.F. (2025) ‘Design, New Materials, and Production Challenges of Bioplastics-Based Food Packaging’, Materials, 18, 673. doi: 10.3390/ma18030673.

Simó-Cabrera, L., García-Chumillas, S., Benitez-Benitez, S.J., Cánovas, V., Monzó, F., Pire, C. and Martínez-Espinosa, R.M. (2024) ‘Production of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) by Haloferax mediterranei Using Candy Industry Waste as Raw Materials’, Bioengineering, 11, 870. doi: 10.3390/bioengineering11090870.

Tilsted, J.P., Bauer, F., Deere Birkbeck, C., Skovgaard, J. and Rootzén, J. (2023) ‘Ending fossil-based growth: Confronting the political economy of petrochemical plastics’, One Earth, 6, pp. 607–619. doi: 10.1016/j.oneear.2023.05.018.

Project name

ViSS. Viable, safe and sustainable PHBV value chain for food packaging applications

Project summary

The ViSS project addresses plastic pollution by developing PHBV, a bio-based, biodegradable polyhydroxyalkanoate, from organic residues. This sustainable alternative to fossil-based plastics offers excellent properties for short shelf-life food packaging, including processability, recyclability and biodegradability in various environments. ViSS aims to create a safe, cost-effective, and circular value chain, promoting market adoption and regulatory alignment for bio-based plastics.

Project partners

The ViSS consortium unites 15 partners from six European countries, offering expertise from bioplastic production to packaging validation. Members include CETEC (Coordinator), CETEC Biotechnology, IRIS Technology, IDENER, University of Alicante, AITEX, KVELOCE, ZUKÁN (Spain); VTT (Finland); Helian Polymers (The Netherlands); PROPA, TECNOALIMENTI, ICONS (Italy); BEAULIEU (Belgium); and University of Birmingham (UK), collectively driving the project’s innovative bio-based solutions.

Project lead profile

The ViSS project is coordinated by Dr Carmen Fernández Ayuso, Head of Coordination and R&D Management at CETEC, the Plastics and Footwear Technology Center of the Region of Murcia. A Chemical Engineering PhD with over 15 years in plastics, Dr Ayuso strategically aligns research efforts with future market needs and technological advancements.

Project contacts

Project Coordinator:

Carmen Fernández Ayuso

Email: coordination@viss-project.org

Communication: Chiara Locuratolo

Email: info@viss-project.eu

Web: viss-project.eu

LinkedIn: linkedin.com/company/viss-project

YouTube: @ViSSproject

Funding

This project has been co-funded by The European Research Executive Agency (REA) and UK Research and Innovation (UKRI) under the European Union’s Horizon Europe research and innovation programme – grant agreement number 101081931.

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union, REA or UKRI. Neither the European Union nor the granting authorities can be held responsible for them.

Figure legends

Figure 1: Flowchart illustrating the biotechnological process of converting food industry waste into PHBV-based ViSS packaging, from fermentation and formulation to final product formats.