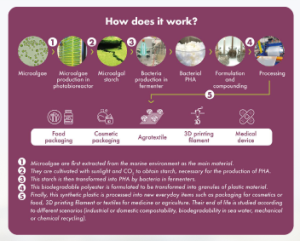

The NENU2PHAR project has developed a collection of commercial packaging applications made of PHA bio-based plastics originating from a sustainable and sourced raw material: microalgae.

The goal of the NENU2PHAR project is to set up a new European value chain of PHA-based bioplastic products with an acceptable end-of-life from an underutilised biological resource. This project, funded by the EU Horizon 2020 programme through the Circular Bio-based Europe Joint Undertaking (CBE JU), gathers 17 partners from both research and industry sectors to develop a new bioplastic value chain starting with CO2-capturing microalgae and ending in various plastic packaging products. This project is ready to offer a new generation of bio-sourced and biodegradable plastic products, mainly packaging solutions, to help reduce marine litter, greenhouse gas emissions and the EU’s dependence on imported fossil fuels.

The European plastic industry

Plastics constitute a vital component of the global economy, with production skyrocketing over the past 50 years, from 15 million tons in 1964 to 359 million tons in 2018, and the trajectory is projected to continue upward. In Europe, the plastics industry provides over 1.5 million direct employment opportunities, supported by nearly 60 000 companies that collectively generated a turnover of 350 billion euros in 2016, with a trade balance approaching 15 billion euros (PlasticsEurope). However, the industry grapples with two significant challenges. A staggering 90 per cent of global plastic production relies on virgin fossil feedstock, resulting in a substantial environmental footprint. Moreover, the plastic industry faces a negative perception due to unsustainable end- of-life management practices, such as incineration, along with increasingly visible and persistent environmental impacts. Given these challenges, it is crucial for the EU to prioritise exploring innovations that foster a more sustainable production of plastics.

Reduce the environmental impact of plastic

To combat their adverse environmental effects, the EU is leading new regulations to address plastic pollution and incentivise plastic producers to explore alternative packaging methods or embrace the development of bioplastics. Single-use plastic products are scheduled for gradual prohibition by 2040, notably following the enactment of the European Directive on Single-Use Plastics. Adopted in 2019, this directive is being implemented in France through the AGEC law (Anti- Waste for a Circular Economy), which aims to halt the production of single-use plastic packaging by 2040. To achieve this ambitious goal, reduction, reuse, and recycling targets have been established by decree, and research initiatives are underway to pioneer innovative plastic solutions.

PHA bio-based plastics

Polyhydroxyalkanoates (PHAs) are a class of renewable, biodegradable and bio-based polyesters. Together with polylactic acid (PLA) and polybutylene succinate (PBS), they are considered to be a green polymer group. It is expected that PHAs could gradually replace conventional plastic materials since they have similar physicochemical, thermal, and mechanical properties to polypropylene (PP) and low-density polyethylene (LDPE), representing more than 70 per cent of the plastic used in packaging. Depending on their chemical

composition, they also feature a wide array of useful physical and mechanical properties, thus allowing for a broader range of applications. In addition, PHA presents a friendly end-of-life as they readily degrade in soil, aquatic media and home and industrial compost.

The fact that PHAs can be obtained by a purely biotechnological process based on the fermentation of carbon-rich biomass feedstocks, such as sugars, makes them particularly attractive. Unfortunately, no sustainable value chain currently exists in Europe, and production schemes developed elsewhere appear highly questionable from an environmental and ethical standpoint. Current carbon feedstocks used as fermentation substrates are usually derived from agricultural resources, such as starch produced from maise, potatoes, wheat and tapioca. Their diversion from food production to producing bioplastics on a massive scale would certainly imply an increase in agricultural commodity prices.

“The best advantage of Nenu2PHAr is that there’s no competition with edible resources. With the use of microalgae, we don’t use any feedstock which is currently used for animal or human nutrition.”

Jean Francois Sassi, Project Coordinator (CEA)

Microalgae as feedstock

At the industrial level, microalgae development allows biomass production in controlled reactors that do not require arable land, eliminating competition with traditional crop/agrifood supply systems. Microalgae capture high quantities of CO2 and generate O2, sugars and lipids that can be converted into carbon- rich feedstock while tackling carbon neutrality goals. Microalgae production systems can be integrated with the recovery of nutrients from waste streams, thus recycling materials and energy and improving the sustainability of industrial processes. EU-based demonstration facilities are already producing microalgal biomass from wastewater treatment processes and improving the regulation of emissions and the water quality required for discharge in water bodies. This, therefore, saves energy and reduces greenhouse gas emissions simultaneously.

The NENU2PHAR project has developed a collection of bio-sourced and biodegradable plastics that offer a valuable alternative to non- biodegradable, petroleum-based plastics.

The applications targeted

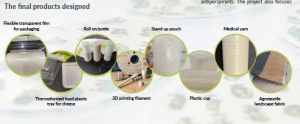

The applications targeted by the NENU2PHAR project encompass diverse fields, including food packaging, cosmetic packaging, 3D printing filament, medical devices and agrotextiles. In food packaging, PHA materials are utilised in various forms, such as flat films for thermoformed packaging, stand- up pouches for dry food, and plastic cups. Cosmetic packaging involves the production of roll-on packaging for liquid cosmetics, offering versatility beyond ants. The project also focuses on developing bio-based filaments suitable for 3D printing, prioritising properties like compostability, recyclability and mechanical strength. Medical devices benefit from PHA’s biodegradability and biocompatibility, particularly in textiles for applications like agrotextiles, 3D printing filaments and medical filaments. Moreover, compostable agrotextiles, including insect netting and groundcovers, are explored to reduce environmental contamination, highlighting PHA’s potential in sustainable agricultural practices.

Key achievements

The following NENU2PHAR project achievements can be considered the most significant and have been selected by the consortium as the most important project KER’s (key exploitation results).

- Producing starch from microalgae to serve as fermentation substrate

- Creating processes to produce and refine starch from microalgae

- Creating fermentation processes using starch hydrolysates from microalgae as feedstock

- Forming a methodology for PHA extraction and purification using greener solvents (compared to conventional chlorinated solvents)

- Expertise in PHA formulation and compounding

- Building knowledge on the processes, methods and technologies for the compounding of PHA

- Using PHA to create trays for cheese slices, cups for compote and stand-up pouches

- Using PHA to create pouches for wet products (yoghurt)

- Using PHA to create cosmetics packaging (roll-on bottles)

- PHA-based formulation for thermoforming with medium-high barrier properties and flexibility

- Recyclability (sorting, mechanical recycling, and composting) of PHA and PHA-based blends.

A multi-stakeholder project

NENU2PHAR brings together

17 European partners, coordinated by the CEA (France)

Four research and technology partners

Alternative Energies (France)

Atomic Energy Commission (France) Innovation Plasturgie Composites (France) ITENE (Spain)

CENTEXBEL (Belgium)

Six SME partners ELIXANCE (France) CELABOR (Belgium) BIO-MI Ltd (Croatia) BIOTREND (Portugal)

LOMARTOV S.L. Applied Innovation Engineering (Spain)

Zero Emissions Engineering B.V.

(The Netherlands)

Four large industrial partners

DANONE (France) KAJ Plastics (Poland)

SOFRADIM Production (France) IFG EXELTO (Belgium) Academic partner

Université de Bretagne Sud – Institut de

recherche Dupuy de Lôme (France)

Innovative cluster

Bioeconomy for Change (France)

Watch: Discover the Nenu2PHAr project value chain

Project summary

Nenu2PHAr : For a sustainable and European value chain of PHA-based materials for high-volume consumer products

Project summary

The goal of this BBI-JU project is to develop across four years an innovative European value chain of PHA (Polyhydroxyalkanoate) based biodegradable bio-based plastics from sustainable and renewable resources: microalgae biomass and selection of bacteria strains. Eight PHA-based products with their respective end-of-life scenarios were developed and benchmarked to their fossil-based counterparts.

Project partners

The consortium comprises 17 partners from seven different European countries, representing various profiles including RTOs, SMEs, large companies, academia and a cluster. They span the entire value chain, from microalgae production to plastic manufacturing, and extend to industrial end-users, encompassing end-of-life analysis.

Project lead profile

The coordinator of the project is the CEA, a French leading research organisation specialising in nuclear and renewable energies, defence and security, information technologies and healthcare. With a multidisciplinary approach, CEA conducts cutting-edge research, fosters innovation and collaborates with industry and academia. The CEA runs ten research centres and six regional technological platforms located all over France, hiring over 16 000 people.

Project contact

Pablo ALVAREZ

Project coordinator

+33 647 620 188

Marine BELLON

Communication contact

+33 695 107 341

m.bellon@bioeconomyforchange.eu https://nenu2phar.eu/

https://www.linkedin.com/company/ nenu2phar/

Funding

Grant agreement no. 887474.