The European manufacturing industry is at a turning point, facing the dual challenge of reducing its environmental footprint while embracing digital transformation. In this context, the Bio-Uptake project, funded under the Horizon Europe programme (GA No. 101057049), aims to accelerate the large-scale adoption of bioplastic composites by developing innovative, flexible and sustainable manufacturing solutions.

Petroleum-based plastics, though widely used, pose significant environmental concerns. Bio-based materials offer a promising alternative, yet their uptake remains limited due to differences in physical and thermochemical properties and the lack of adaptable manufacturing processes. Bio-Uptake addresses this gap by introducing a modular approach based on high-performance intermediate formats—organosheets, tapes and pellets—made from bio-based materials.

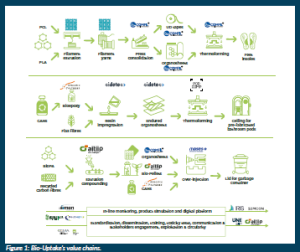

The project’s ambition is to increase the use of bioplastic composites by 39%, demonstrating their viability across three key sectors: construction, medical and packaging. By combining green chemistry, advanced manufacturing technologies and digital tools such as simulation and in-line monitoring, Bio-Uptake paves the way for a new generation of bio-based products that meet both technical and environmental standards (Figure 1).

Coordinated by AITIIP, the consortium brings together 14 partners from seven European countries (Figure 2). Their collective expertise ensures that Bio-Uptake not only delivers technological innovation but also contributes to circular-economy principles, workforce training and standardisation efforts, laying the foundation for a more sustainable and resilient European industry.

Objectives and innovation

Bio-Uptake is built on a clear, ambitious roadmap structured around nine specific objectives, each addressing a key barrier to the widespread adoption of bioplastic composites in industry.

At the core of the project lies the development of three disruptive manufacturing processes, each tailored to a different type of material: thermoset composites, highly customised thermoplastics and large-volume thermoplastics. These products are designed to outperform fossil-based alternatives in terms of performance, adaptability and sustainability.

To support these innovations, Bio-Uptake is upgrading six conformal manufacturing technologies, including filament extrusion, resin impregnation, press consolidation and over-injection, ensuring they are compatible with bio-based materials and scalable across sectors. These technologies are enhanced through the integration of a smart, end-to-end digital platform that combines design, simulation, in-line monitoring and quality diagnosis to ensure process interoperability and product consistency.

A key innovation is the creation of four new intermediate formats: thermoset organosheets, mono- and bi-component thermoplastic organosheets, unidirectional tapes and thermoplastic pellets. These semi-finished products offer modularity and flexibility, enabling manufacturers to tailor material properties to specific applications.

Bio-Uptake’s impact is demonstrated through three real-world value chains: construction, medical and packaging. In each, a representative product is developed using more than 75% bio-based content: a bathroom ceiling cabinet, a foot orthosis and a garbage container lid (Figure 3). These products are validated against technical and environmental standards, showcasing the feasibility of bio-based alternatives.

The project also pioneers circularity by design, leveraging Covalent Adaptable Networks (CANs) and eco-design principles to enable reuse, remanufacture and recycling. This is complemented by two training programmes targeting young scientists and industrial workers, and by contributions to standardisation efforts across the three value chains.

Bio-Uptake’s innovation strategy is structured around three pillars:

- Functionality: The use of high-performance intermediate formats allows for enhanced mechanical, thermal and chemical properties. These formats—organosheets, tapes and pellets—are designed to be lightweight, customisable and multifunctional.

- Digitalisation: A digital twin architecture enables seamless data flow across the product lifecycle, from design to quality control. This includes simulation tools (CADMOULD, TSIM), in-line monitoring (sensors, photonics) and non-destructive testing, ensuring traceability and process optimisation.

- Sustainability: Bio-based CANs enable thermosets to behave like thermoplastics, allowing reshaping and recycling. Reversible adhesives facilitate the separation of components, supporting circularity without compromising performance.

These innovations position Bio-Uptake as a transformative project that bridges the gap between material science, digital engineering and sustainable manufacturing.

Implementation and use cases

To validate its technological innovations, Bio-Uptake is implementing its solutions across three strategic manufacturing sectors: construction, medical and packaging. These sectors were selected for their high material consumption, diverse technical requirements and potential for circularity.

In the construction sector, Bio-Uptake replaces traditional epoxy-glass fibre sandwich panels with a semi-automated process using bio-based organosheets. These sheets are pre-impregnated with a 3R-CANs epoxy resin derived from lignin and reinforced with flax fabric. The sandwich structure includes a wood core bonded with a reversible adhesive, enabling future separation and recycling.

Compared to conventional vacuum infusion, this process is 30% faster, reprocessable and recyclable, with no need for refrigerated resin storage. The result is a high-performance, lightweight ceiling cabinet that meets structural and environmental standards.

Orthopaedic insoles traditionally involve manual assembly of multiple layers, using fossil-based materials and time-consuming processes. Bio-Uptake introduces a one-shot free-forming technique combining press consolidation and thermoforming of bio-based organosheets and unidirectional tapes.

Materials such as PLA and PCL allow anatomical adaptation through reheating, a feature not possible with conventional epoxy or carbon fibre. The new process is 34% more efficient, 12% less costly and 50% faster, while enabling the use of bio-based materials previously considered unsuitable for medical applications.

Large-scale packaging products, such as garbage container lids, are typically made from oil-based polyethylene and EPDM rubber. Bio-Uptake replaces these with a hybrid structure combining self-reinforced PLA organosheets and biopolyamide pellets reinforced with lignin-carbon and wood fibres.

This approach reduces the lid’s weight by 35% and the plastic content by 22%, while maintaining mechanical performance for outdoor use. A reversible adhesive enables component separation, supporting remanufacturing and recycling.

Advanced characterisation and in-line monitoring ensure precise control over micro- and macro-structures, including polymer crystallinity, fibre orientation and porosity. This allows manufacturers to tailor material properties to specific applications, enhancing product quality and performance.

The project’s digital infrastructure supports flexible production models, integrating simulation, monitoring and quality assurance tools. This enables manufacturers to adopt bio-based materials without major equipment changes, lowering barriers to entry and fostering widespread adoption.

Consortium and impact

The multidisciplinary team ensures that Bio-Uptake covers the full innovation spectrum, from materials science and process engineering to digitalisation, the circular economy and market deployment. The consortium’s geographical diversity also supports the project’s ambition to create a European-wide impact, fostering knowledge exchange and harmonisation across borders.

On the industrial side, the project promotes technology transfer and scalability, enabling manufacturers to adopt bio-based materials without major infrastructure changes. The use of modular formats and digital tools supports flexible, decentralised production models, reducing costs and increasing accessibility for SMEs.

By replacing fossil-based materials with bio-based alternatives, Bio-Uptake contributes directly to the European Green Deal and Circular Economy Action Plan. The project’s emphasis on recyclability, remanufacturability and eco-design ensures that sustainability is embedded throughout the product lifecycle.

Bio-Uptake also addresses the skills gap in green manufacturing by developing two targeted training programmes: one for young scientists and engineers, and another for the industrial workforce.

These programmes foster a new generation of professionals equipped to lead Europe’s twin transition.

To support long-term adoption, Bio-Uptake contributes to standardisation efforts across the three value chains. This includes defining technical specifications, quality benchmarks and circularity metrics for bio-based products.

Through its collaborative structure and holistic approach, Bio-Uptake is not only advancing technology but also shaping the future of sustainable manufacturing in Europe.

Conclusion

Bio-Uptake is more than a research project—it is a blueprint for transforming the European manufacturing landscape. By combining advanced materials science, smart manufacturing technologies, and circular-economy principles, the project demonstrates that bioplastic composites can meet the highest industrial standards while reducing environmental impact.

Through its modular approach, Bio-Uptake enables manufacturers to tailor bio-based materials to specific applications, overcoming the limitations of conventional plastics. Its digital infrastructure ensures process reliability and scalability, while its commitment to circularity guarantees that sustainability is not an afterthought, but a design principle.

The project’s real-world demonstrations in the construction, medical, and packaging sectors prove that bio-based products are not only feasible but also competitive. Supported by a strong consortium and aligned with EU policy goals, Bio-Uptake is paving the way for a new era of smart, green and inclusive manufacturing.

Bio-Uptake is paving the way for a new era of smart, green and inclusive manufacturing.

Project summary

Bio-Uptake aims to boost the adoption of bioplastic composites in European manufacturing through innovative processes, digital tools and circular design. Demonstrated in construction, medical and packaging sectors, the project develops modular intermediate formats and promotes sustainability, training and standardisation.

Project partners

Bio-Uptake is coordinated by AITIIP, a Spanish technical institute with extensive expertise in advanced manufacturing and biocomposites. The project brings together a diverse consortium of 14 partners from seven EU countries, representing a balanced mix of research organisations, industrial players, SMEs and innovation hubs.

Project lead profile

Bio-Uptake thrives thanks to the dedication of scientists, engineers, researchers and innovators from across Europe. Their combined expertise in materials, manufacturing, digitalisation and sustainability drives the project’s success. Together, they co-develop solutions, validate technologies and promote circularity, making Bio-Uptake a true collaborative effort that is shaping the future of bio-based manufacturing in Europe.

Project contacts

Nicolas Longhitano – POLYMERIS

Email: nicolas.longhitano@polymeris.fr

Web: www.bio-uptake-project.eu

X: @BioUptake

LinkedIn: /company/bio-uptake/

YouTube: @biouptake

Funding

The BIO-UPTAKE project has received funding from the European Union under the grant agreement No. 101057049.

Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union. Neither the European Union nor the granting authorities can be held responsible for them.

Figure legends

Figure 1: Bio-Uptake’s value chains.

Figure 2: Bio-Uptake Consortium.

Figure 3: Demonstrators from left to right, ceiling for bathroom pod, feet insoles and lid for garbage container.