The ViSS project holds an ICT platform that integrates three interoperable web-based tools for traceability, evaluation, decision-making and communication. This ensures real-time data capture and accessible reporting across the PHBV bio-packaging value chain.

Leveraging a module-based architecture and an easy-to-use approach, the platform covers all the transformation of materials from residues to the final transformation into functional products. Not only this, but it also supports Safe and Sustainable by Design (SSbD) evaluations and stakeholder engagement. This article describes the platform’s conceptual underpinnings, methodological approach, technical implementation and preliminary results, demonstrating its potential to enhance transparency and decision-making in circular bioeconomy contexts.

Introduction

Digitalisation is increasingly recognised as a cornerstone for accelerating the transition towards a circular and sustainable bioeconomy. By enabling the systematic collection, processing and sharing of information across value chains, digital infrastructures not only ensure transparency and traceability but also create the conditions for robust, evidence-based decision-making. This is particularly relevant in the context of novel bioplastics such as PHBV, where compliance with strict EU regulations and the operationalisation of SSbD principles are essential for ensuring viability, safety and social acceptance (European Research Executive Agency (REA), 2023).

Nevertheless, this digital transformation faces several challenges. Data heterogeneity and fragmentation demand interoperable solutions capable of linking residues, materials, processes and final products in real time (Ortiz Aragón, Jaime 2024a). Equally important is ensuring the reliability and security of such data, as these are sensitive contexts such as food-contact applications. In parallel, user-friendly tools are required to foster engagement across the whole spectrum of stakeholders, from technical partners and industry actors to consumers and civil society organisations.

Beyond technical aspects, the ViSS project also addresses structural challenges. Firstly, while the EU strongly promotes the SSbD approach, integrated methodologies for applying it holistically within the bio-based plastics sector are still at an early stage. Secondly, consumer

and industrial end-user acceptance is crucial for the market penetration of sustainable food packaging, but there is little systematic knowledge or reliable tools (such as the Social Readiness Level (SRL)) to assess and enhance this acceptance. Finally, consumer scepticism is reinforced by the lack of trusted information and the prevalence of misleading or ‘greenwashed’ claims, which undermine confidence and marketability of bio-based plastics (European Research Executive Agency (REA), 2023).

The ViSS ICT Platform has been conceived to directly respond to these needs. Its three interoperable modules, the Traceability Tool, the Evaluation and Decision Tool, and the Public Tool, form a digital backbone for the project. Together, they ensure data integrity and transparency, operationalise a novel SSbD evaluation framework applicable across the entire PHBV value chain and integrate social readiness considerations into a structured SRL methodology that supports adoption and replication. Through this combined approach, the platform not only improves internal decision-making but also empowers external stakeholders with accessible, reliable insights, thereby fostering trust, transparency and market uptake (Ortiz Aragón, 2024b).

Methodology

An Agile software development life cycle (SDLC) structured the platform’s creation. This includes requirements elicitation via the identification of technical partners’ needs, to define user stories and key data elements (KDEs). Based on this approach, iterative sprints are taken, each delivering prioritised features for one tool module, with continuous integration and stakeholder demos and usability testing, employing scenario-based evaluations on desktop and mobile devices to refine UI/UX.

The backend is implemented in Laravel (PHP), utilising Eloquent ORM for MySQL database interactions and securing RESTful endpoints with Laravel Sanctum’s token-based authentication. All application code resides in a private GitHub repository, which drives the CI/ CD pipeline: each push automatically triggers build, test and deployment stages to the dedicated server.

On the frontend, the UI is built atop the Material Dashboard template, which leverages Bootstrap Material Design (Ortiz Aragón, Jaime 2024a).

Results

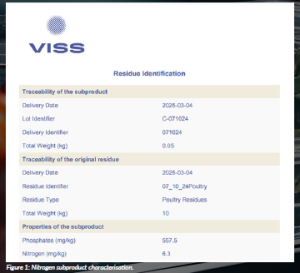

The Traceability Tool demonstrates robust capabilities for end-to-end provenance tracking of both sugars and poultry residues. Users initiate the workflow by scanning or generating a QR code tied to a unique waste-stream identifier; this action immediately records the entries. For example, after the hydrolysis, a new subproduct in the form of a useful nitrogen source is obtained from residues. This product can be traced both forward, to observe its use in a fermentation process, and backwards, to determine its origin (Ortiz Aragón, 2024a). Figure 1 shows an example of a reported batch. Operators register each sub-batch, such as nitrogen and phosphorus streams, through a dedicated form, producing tailored reports for downstream partners. Moreover, the tool’s reporting interface supports composite ‘traceability matrices’ whereby a single view links original residue IDs to subproduct identifiers and final PHBV lot numbers, enabling auditors to reconstruct the full chain of custody with minimal effort. This real-time integration of mobile scanning, cloud storage and immutable logging reduces manual reconciliation errors (Ortiz Aragón, Jaime 2025).

The Evaluation and Decision Tool has likewise matured into a dynamic decision-support environment. Technical partners can select multiple SSbD indicators spanning hazard properties, lifecycle impacts and social readiness, and enter measured values through an intuitive form. Once the benchmarks are set, the system calculates composite scores on the fly, displaying results in both tabular and graphical formats (See example in Figure 2) (Matamoros et al., 2024; Caldeira et al., 2022). Each time a new evaluation is submitted, the dashboard graphs and tables update instantly, allowing side-by-side comparisons of process variants and benchmarking against market-standard alternatives. This functionality aims to accelerate iterative optimisation cycles (Ortiz Aragón, 2024b).

Finally, the Public Tool is entering its initial rollout phase, designed to translate ViSS outcomes into accessible insights for non-technical audiences, in alignment with the Digital Product Passport (DPP) initiative. While the underlying data feeds are still being finalised, the framework will feature interactive visualisations of material provenance, SSbD scores and end-of-life recommendations. The primary objective is to provide consumers and civil society organisations with reliable information that raises awareness of the impacts of sustainable packaging. In parallel, communication and dissemination strategies will refine which metrics and narratives resonate most effectively with each stakeholder group, ensuring that when the Public Tool goes live, it fosters both transparency and engagement (Ortiz Aragón, 2024a; Ortiz Aragón, 2024b).

Conclusions

The ViSS ICT Platform demonstrates a viable approach for integrating traceability, multi-criteria evaluation and public engagement in circular bioeconomy projects. Its blockchain-inspired architecture ensures data integrity, while Agile-driven development produces user-friendly tools across desktop and mobile environments. Future work will expand partner onboarding, incorporate predictive analytics and evaluate long-term impacts on supply-chain transparency.

References

Caldeira, C., Farcal, R., Garmendia Aguirre, I., Mancini, L., Tosches, D., Amelio, A., Rasmussen, K., Rauscher, H., Riego Sintes, J. and Sala, S. (2022) Safe and sustainable by design chemicals and materials – Framework for the definition of criteria and evaluation procedure for chemicals and materials. EUR 31100 EN. Luxembourg: Publications Office of the European Union. doi: 10.2760/487955.JRC128591.

European Research Executive Agency (REA) (2023) ViSS Project Grant Agreement (Project 101081931 – VISS, B.3 – Biodiversity, Circular Economy and Environment).

Matamoros, A., Benedicto-Royuela, J., Ferrando, M., López Abelairas, M., González, S., Sarvola, I.-M., Behm, K. and Karjalainen, E. (2024) D6.3 SSbD and Social Readiness Evaluation Framework. Public deliverable, ViSS Project. Available at: https://cordis.europa.eu/project/id/101081931/results.

Ortiz Aragón, J. (2024a) D6.2 ViSS Sensitive ICT Platform. Sensitive deliverable, ViSS Project. Unpublished, not publicly available.

Ortiz Aragón, J. (2024b) D6.1 ViSS Non-Sensitive ICT Platform. Public deliverable, ViSS Project. Available at: https://cordis.europa.eu/project/id/101081931/results.

Ortiz Aragón, J. (2025) D6.5 Second Integration and Assessment of Data in ICT Platform. Public deliverable, ViSS Project. Available at: https://cordis.europa.eu/project/id/101081931/results.

Project summary

The ViSS project addresses plastic pollution by developing PHBV, a bio-based, biodegradable polyhydroxyalkanoate, from organic residues. This sustainable alternative to fossil-based plastics offers excellent properties for short shelf-life food packaging, including processability, recyclability, and biodegradability in various environments. ViSS aims to create a safe, cost-effective, and circular value chain, promoting market adoption and regulatory alignment for bio-based plastics.

Project partners

The ViSS consortium unites 14 partners from five European countries, offering expertise from bioplastic production to packaging validation. Members include CETEC (Coordinator), CETEC Biotechnology, IRIS Technology, IDENER, University of Alicante, AITEX, KVELOCE, ZUKÁN (Spain); VTT (Finland); Helian Polymers (The Netherlands); PROPA, TECNOALIMENTI, ICONS (Italy); and University of Birmingham (UK), collectively driving the project’s innovative bio-based solutions.

Project lead profile

The ViSS ICT Platform is led by Jaime Ortiz Aragon, Project Technician at CETEC, the Plastics and Footwear Technology Center of the Region of Murcia. A computer engineer with four years of experience in the plastic-sector digitalisation. Mr Ortiz aligns development efforts with future market needs and technology advancements.

Project contacts

Project Coordinator: Carmen Fernández Ayuso

Email: coordination@viss-project.org

ICT Platform leader: Jaime Ortiz Aragón

Email: j.ortiz@ctcalzado.org

Communication: Chiara Locuratolo

Email: info@viss-project.eu

LinkedIn: /company/viss-project/

YouTube: @ViSSproject

Funding

This project has been co–funded by the European Research Executive Agency (REA) and UK Research and Innovation (UKRI) under the European Union’s Horizon Europe research and innovation programme (Grant agreement No. 101081931).

Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union, REA or UKRI. Neither the European Union nor the granting authorities can be held responsible for them.

Figure legends

Figure 1: Nitrogen subproduct characterisation.

Figure 2: Example of graphs for an evaluation on the different dimensions.